Core tasks

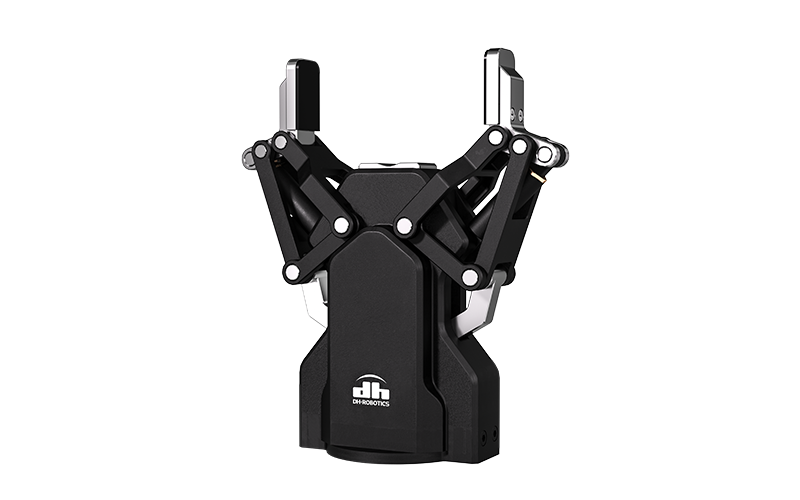

Based on the self-developed servo control system with precision force control as the core, DH-Robotics provides customers in various industries around the world with a variety of intelligent grasping products, which are well adapted to various scenarios such as detection, sorting, handling, and assembly, it provides higher accuracy, better usability and stronger stability for intelligent manufacturing capabilities .

Handling and positioning of small workpieces

The PGE series industrial slim-type parallel electric gripper was applied to complete the handling, positioning and precision assembly of extremely small work-pieces.

Application Products

Randomly grabbing and positioning

The AG series electric gripper and industrial robots were applied to complete the task of random grasping and positioning of special-shaped objects.

Application Products

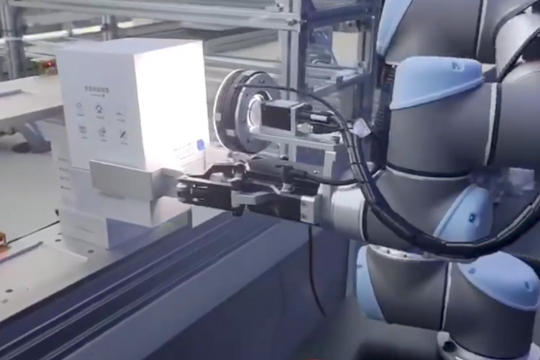

Shelf picking and mobile handling

The “electric gripper + collaborative robot + AGV” collocation was applied to complete shelf picking and mobile handling in the new retail field, and the delivery process is unmanned.

Application Products

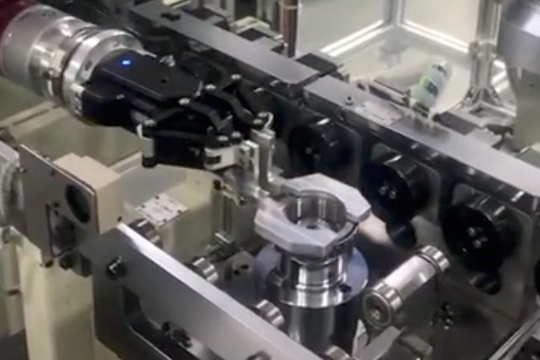

Parts clamping, handling, positioning and assembly

The AG-160-95 adaptive gripper was applied with a collaborative robot to complete the clamping, handling, positioning and assembly of parts.

Application Products

Production equipment loading and unloading and material handling

With the combination of “AGV+collaborative robot+electric gripper +vision system”, the PGI-140-80 with large gripping force, big stroke , and precise force control meets the needs of loading and unloading and handling materials in production equipment. The adjustable ability of PGI also perfectly adapts to the frequent replacement of materials in actual production

Application Products

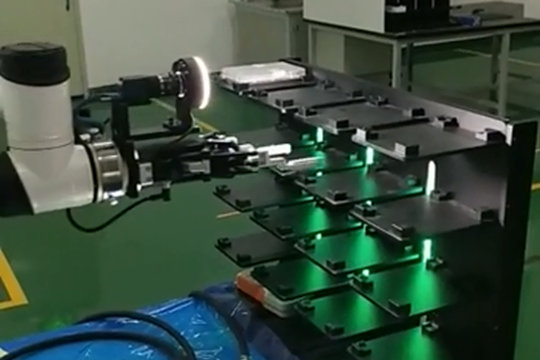

VR glasses lens inspection

In this application, the lens was gripped for surface inspection and to scan the QR code. Compared to the suction cup solution with pneumatic gripper for picking&placing which is easy to cause the damage on the lens, our PGE-5-26 electric gripper with precise force control will protect the lens and also able to grip lens with different size.

Application Products

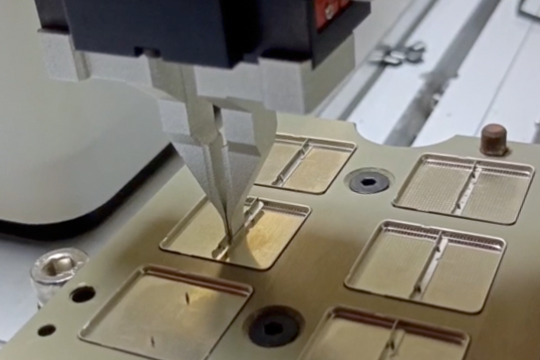

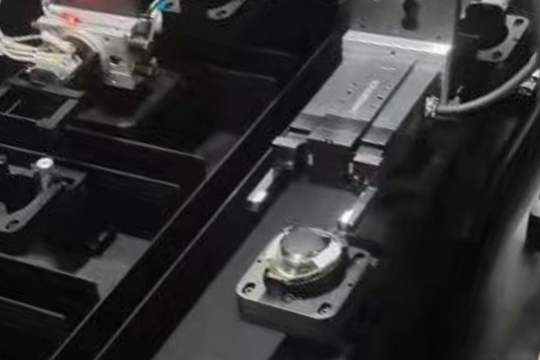

Chips Pick & Place

For chip handling on wafer sorters in the semiconductor industry, vacuum suction cups are traditionally used to pick &place chips. Due to insufficient vacuum of the suction cups, there is a risk of falling during handling, so the electric gripper of PGE-2-12 is applied in this application.

Advantages of the PGE series: It can achieve precise force control, high repeat position accuracy, and non-destructive grabbing of chips.

Application Products

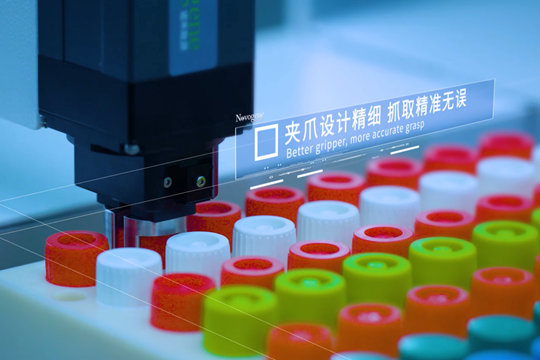

96-well plate storage and handling

The unmanned laboratory is not only embodied in the sample preparation link. Through the combination of “AGV + Six-axis Robot + Electric Gripper + 3D vision”, the 96-well plate reagent kit handling task after the sample is divided into cups can also be unmanned. DH-Robotics electric grippers can complete the task of picking and unloading materials, transfer the 96-well plate to the storage bin, or transport the processed sample box to the testing equipment to stabilize the grip and ensure the safety of the sample during transportation.

Application Products

Laboratory automation applications

The combination of “DH-Robotics Electric Gripper + Robot Arm” could complete the entire process application of small laboratory automation on the desktop. From gripping, weighing, liquid withdrawal, closing the lid to returning to the original position, the whole process is dominated by electric gripper and mechanical arm, which can realize completely unmanned operation.

Application Products

Multifunctional sample preparation station

The multi-functional sample preparation workstation built by the six-axis manipulator platform can realize fully automatic unattended sample preparation. DH-Robotics AG series/PGC series electric grippers can complete complex tasks such as loading and unloading, opening and closing lids, and transportation. The samples are transported in the sample bin, liquid handling, shaking extraction, and centrifugal separation modules to ensure high sample preparation. Throughput, full automation, accuracy, and safety.

Application Products

Unmanned new Coronavirus detection

More possibilities for unmanned Coronavirus detection and throat swab sampling: The solution is AGV with two RGI rotating grippers and one PGE parallel electric gripper to complete the collection of collectors, sampling, test tube opening, storing samples, and closing lids , Disinfection and all the above processes. No human intervention is required during the whole process.

Application Products

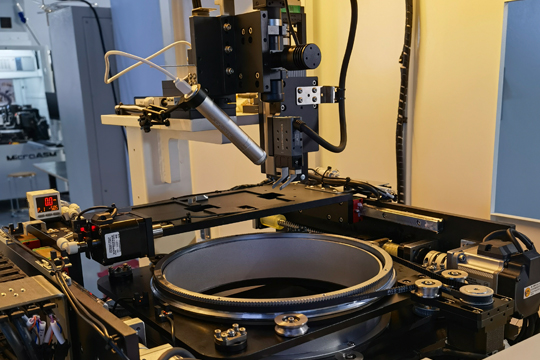

Nucleic Acid Virus Cupping Apparatus

The sub-cup process transplants the scattered reagents into the reagent kits for batch processing and testing (24, 48, 96-well plates) which meet the international standards. In this process, the application of electric grippers can maintain the cleanliness of the kit and samples to the greatest extent.

The virus tube was gripped and rotated for scanning the sampling information.

Application Products

Automated cup processing system

The automatic sub-cup processing system, through ABB’s Scara robotic arm and DH-Robotics electric gripper, can automatically complete the operation of sample tube opening, scanning, information entry, pipetting, turning plate, and closing lid. The whole process is in a closed negative pressure state to ensure that the sample is clean and free from contamination.