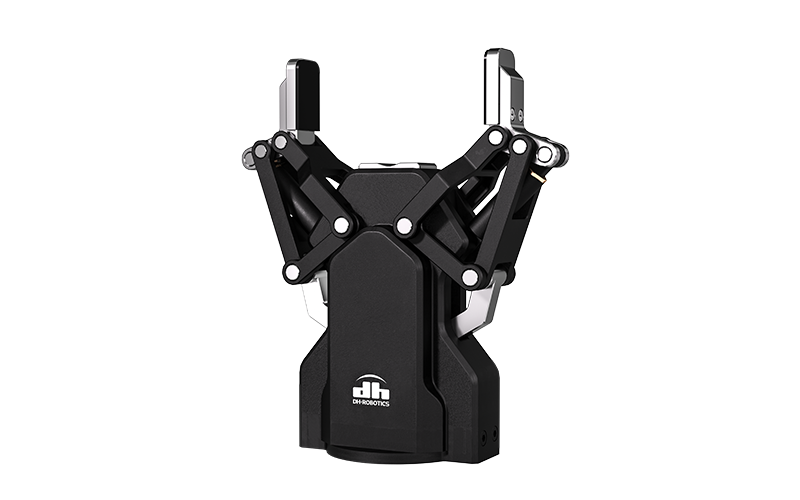

Core tasks

Based on the self-developed servo control system with precision force control as the core, DH-Robotics provides customers in various industries around the world with a variety of intelligent grasping products, which are well adapted to various scenarios such as detection, sorting, handling, and assembly, it provides higher accuracy, better usability and stronger stability for intelligent manufacturing capabilities .

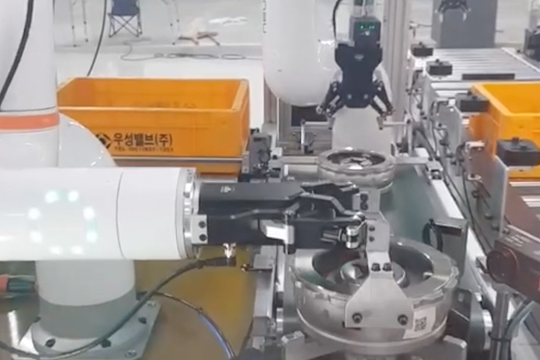

Auto parts assembly loading and unloading

The application from the auto parts industry uses collaborative robots with AG-160-95 adaptive electric gripper. The human-machine collaborated together to complete the precise loading and unloading tasks in the assembly process of auto parts.

Application Products

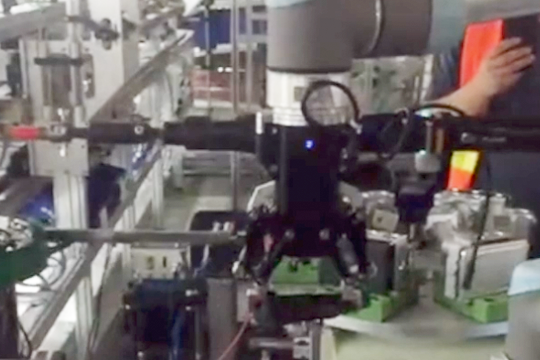

Loading and unloading with vision inspection on auto parts

The AG-160-95 electric gripper was applied with collaborative robots to pick& place auto parts, then complete visual alignment inspection.

Application Products

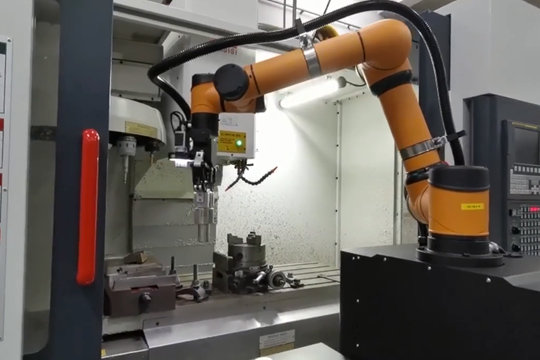

Machine tool loading and unloading and machine tool equipment management

The AG-160-95 electric gripper was applied with AGV and COBOT to complete machine tool loading and unloading and machine tool equipment management.

Task difficulty: precise force control, position control, envelope capture, one machine with multiple functions.

Application Products

Production equipment loading and unloading and material handling

With the combination of “AGV+collaborative robot+electric gripper +vision system”, the PGI-140-80 with large gripping force, big stroke , and precise force control meets the needs of loading and unloading and handling materials in production equipment. The adjustable ability of PGI also perfectly adapts to the frequent replacement of materials in actual production

Application Products

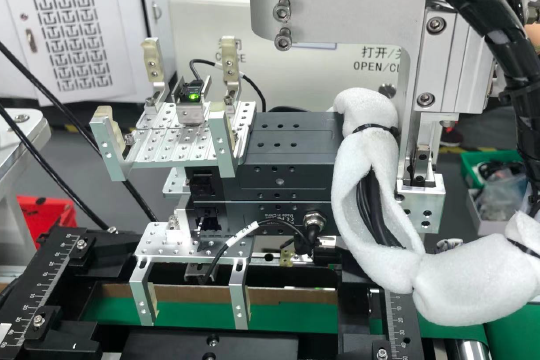

IGBT module detection loading and unloading

The application of automatic loading and unloading with electric gripper is from IGBT module (for new energy vehicles) of testing equipment in the semiconductor industry. With sensors and SCARA robots, dual-grippers for simultaneous is loading and unloading of IGBT modules, equipment could frequently change materials. The PGE-50-26 and PGI-140-80 with large stroke, high clamping force electric jaws, are compatible with materials of different sizes.

Application Products

Mobile phone detection loading and unloading

In Mobile phone audio detection process section, robot equipped with grippers is picking and placing the mobile phones. The PGE series of industrial thin parallel electric gripper can quickly complete the equipment deployment of product changeovers. The electric gripper have large strokes and strong compatibility. They can hold mobile phones of different sizes. With integrated design and precise force control, the grippers could complete the task without any external sensor.

Application Products

Multifunctional sample preparation station

The multi-functional sample preparation workstation built by the six-axis manipulator platform can realize fully automatic unattended sample preparation. DH-Robotics AG series/PGC series electric grippers can complete complex tasks such as loading and unloading, opening and closing lids, and transportation. The samples are transported in the sample bin, liquid handling, shaking extraction, and centrifugal separation modules to ensure high sample preparation. Throughput, full automation, accuracy, and safety.