With development of automation industry, it is an inevitable trend for automation actuating parts to develop in the direction of intelligence, electrification and integration. As one of the key components of precision processing and manufacturing, electric cylinder plays an important role in intelligent manufacturing fields such as 3C electronics, new energy, semiconductor, LCD panel, automobile and laboratory automation.

In the production line application, intelligent electric cylinder is electromechanical integration, highly integrated intelligent electric actuation unit compared with the traditional combined linear module. In recent years, enterprise production has put forward higher requirements for equipment space, precision and efficiency driven by the ever-changing market demand in down stream industries.

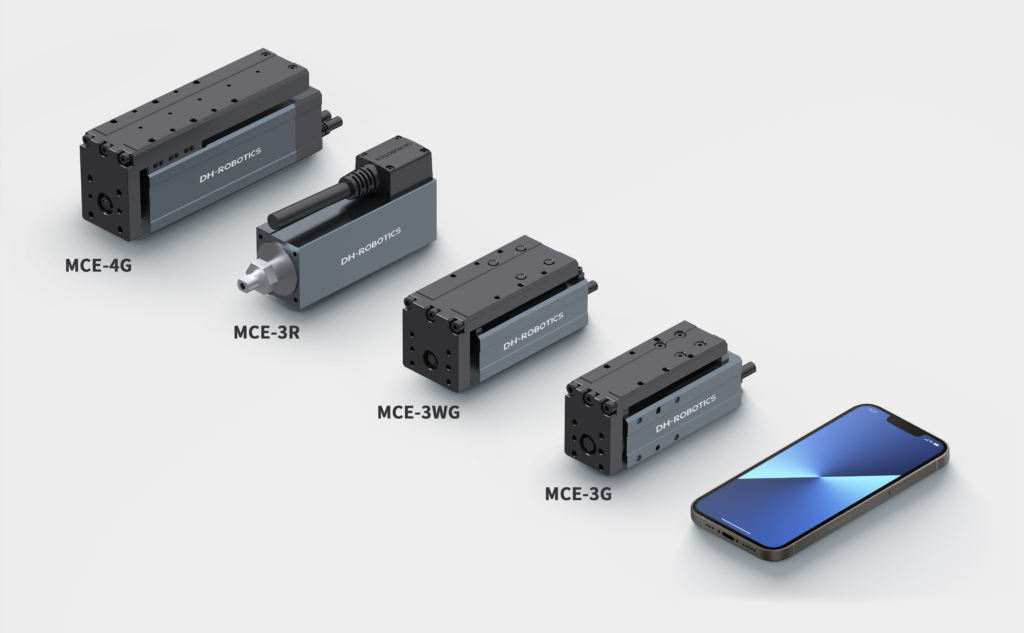

In order to meet the market demand of high-end precision manufacturing, DH-Robotics has launched the MCE series of miniature servo cylinders, including MCE-3G, MCE-3WG, MCE-3R, MCE-4G and other sub-series. Those external dimensions are similar to cylinders, which can effectively replace and upgrade cylinders. The performance is also better than the general stepper cylinder to meet the needs of more manufacturing scenarios.

MCE series is a miniature servo electric cylinder developed and produced by DH-Robotics. Based on advanced self-research precision force control technology and integrated technology, it realizes compact size, high rigidity, large load, fast response, high stability, and excellent repeat positioning accuracy and motion trajectory planning.

Compared with traditional stepper/servo cylinders, MCE series cylinders are eliminating wearing parts such as timing belt, guide sleeve and coupling, and designed and optimized with the integration of mechanical drive mechanism, motor and controller. It have obvious advantages in performance, size, noise and life time. In addition, compared with the stepper cylinder, MCE series use servo motor can have higher speed, and the torque will not drop when the speed increases, which means the acceleration section of the servo cylinder will be shorter, and can adapt to the higher load and fast production scenario needs.

At present, the MCE series has achieved stable mass production and has been applied to mass production and has been applied to many Top-tier customers in 3C electronics, semiconductor, new energy, automotive and other fields, efficiently completing the positioning, deflection, assembly, handling, jacking, pushing, testing, load shifting and other applications of production line objects.

Product Advantages

1、Highly integrated design, small size and space-saving device delopyment

With a minimum width of only 30mm, the MCE series is ingeniously designed with servo motors embedded into the overall structure. It is achieving a highly integrated design with drive control in one unit, eliminating the need for external or folded motors, effectively avoiding the shortcomings of traditional electric cylinders, and providing better performance, accuracy, noise, and lifetime. In addition, due to the miniaturization advantage of MCE series, it can be easily deployed in small equipment space, and its all-in-one controller option, which does not need to occupy the space of electric control cabinet, helps to improve equipment integration and aesthetics.

2、High energy density, excellent load capacity

MCE series adopts high rigid structure design, with high performance linear guide, the maximum load in horizontal direction is 15kg, and the maximum load in vertical direction is 6kg, achieving the best balance between high performance and light weight. In the Z-axis action, the layout can be placed in the projection range of the pushed/lifted object, saving design space while the bearing direction of the guide and screw is better.

3、Fast speed and high linear accuracy, suitable for high-speed and high-precision scenario operation requirements

MCE series is equipped with high performance servo motor and high precision screw guide, with repeat positioning accuracy up to ±0.003mm, maximum running speed up to 1000mm/s and maximum acceleration up to 3000mm/s². While moving at high speed, it can smoothly realize the basic functions of pushing, pulling, pressing, positioning, etc. Its position, speed and thrust parameters are adjustable to complete complex tasks of handling, arranging, picking and placing, and shifting loads.

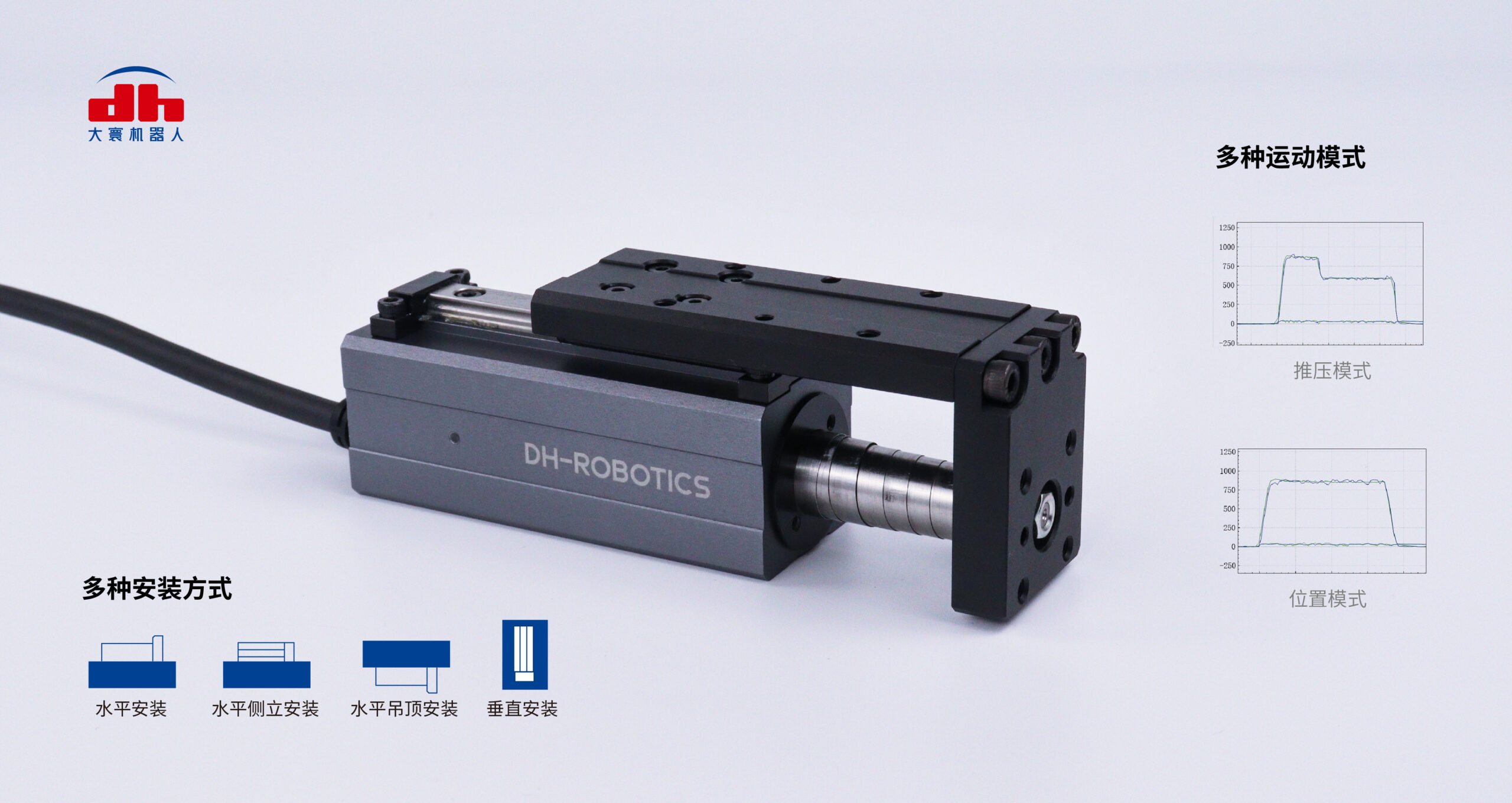

4、Multiple motion positions can be flexibly configured for easy control

MCE series electric cylinder can be connected to PLC with built-in controller to realize plug-and-play, and the control software developed by Daewan can flexibly select position mode and push mode. In addition, the electric cylinder has rich mounting holes, supporting horizontal and vertical multi-directional installation, while the product can be selected out of the line direction, making the deployment of production lines more convenient.

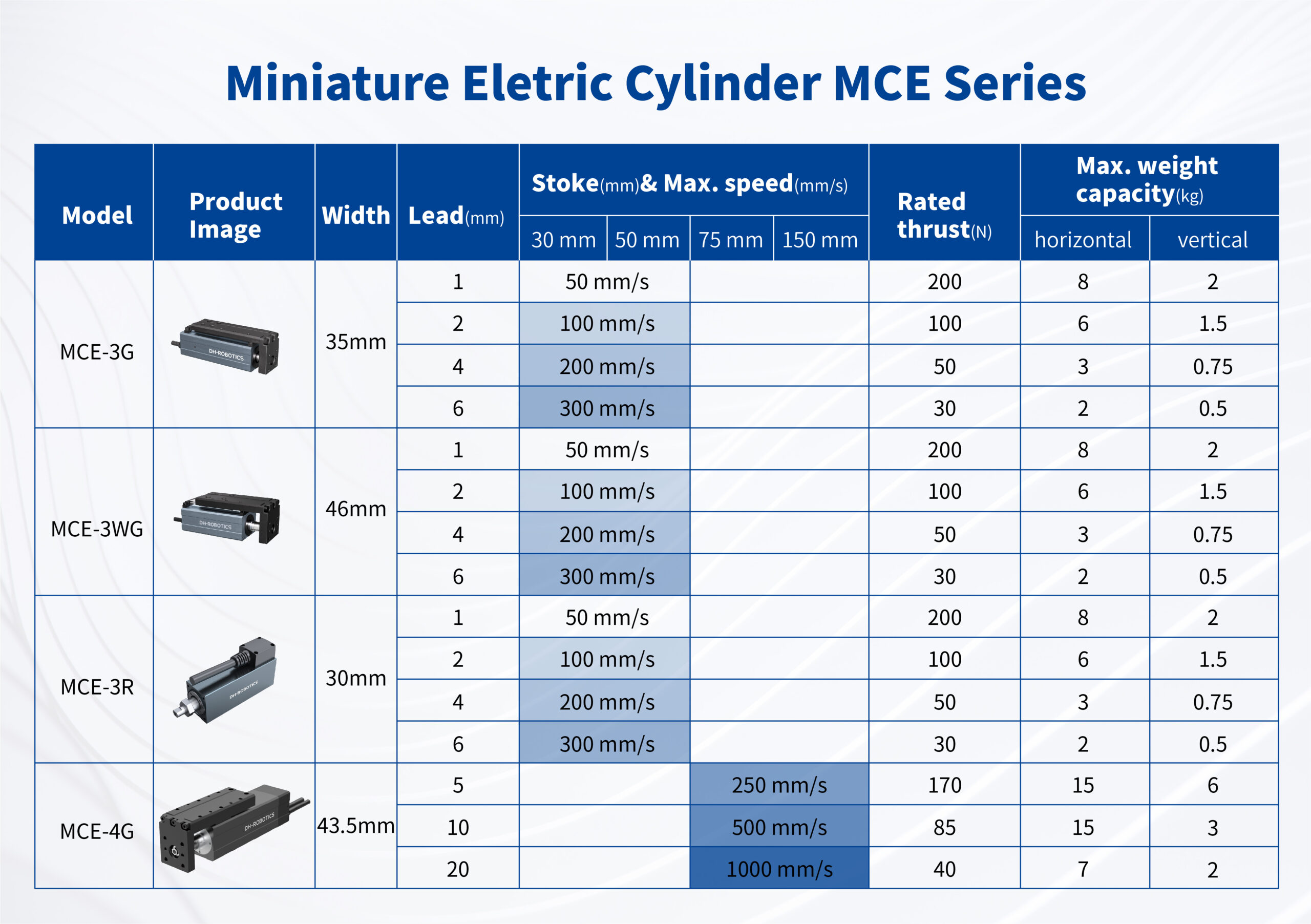

Product Parameter

*For specific product selection and related information, please consult with DH-Robotics technical sales and confirm the application and process

Application Examples

DH-Robotics has launched four series of miniature servo electric cylinders, CE-3G, CE-3WG, MCE-3R and MCE-4G, which can be selected as built-in or external controller according to the application conditions to meet the precision motion control needs of different application scenarios.

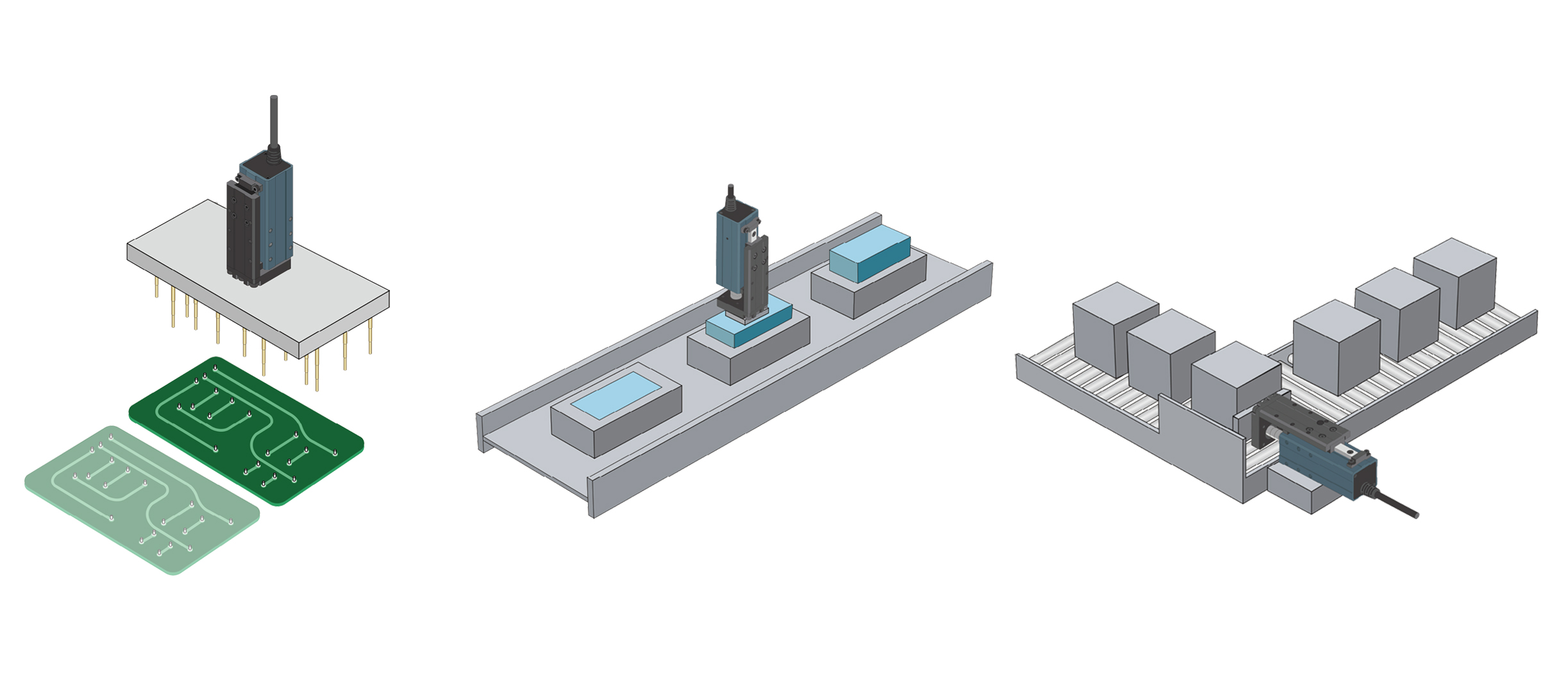

- 3Celectronics/semiconductor industry

By using MCE series miniature servo electric cylinder to lift the probe head, the probe head will quickly and frequently contact the circuit board and electronic components to complete the circuit board conduction performance testing; chip, integration block and other different electronic components pin pushing and inserting applications, MCE electric cylinder can apply greater downward pressure on top of the electronic components to complete the pin insertion of electronic components, etc.; 3C electronic components pallet transfer applications, replacing 3C electronic components pallet transfer application, replace the manual repetitive work on the production line, complete multi-point position work at the same time to achieve a smooth and fast automated production.

Positioning detection, assembly pushing and inserting, pushing and shifting

In the above application, the position, speed and thrust parameters of MCE electric cylinder are adjustable, which can be programmed to precisely control the position and achieve soft landing and pushing, protecting fragile workpieces from damage while operating smoothly and efficiently, meeting the needs of flexible production in 3C/semiconductor industry.

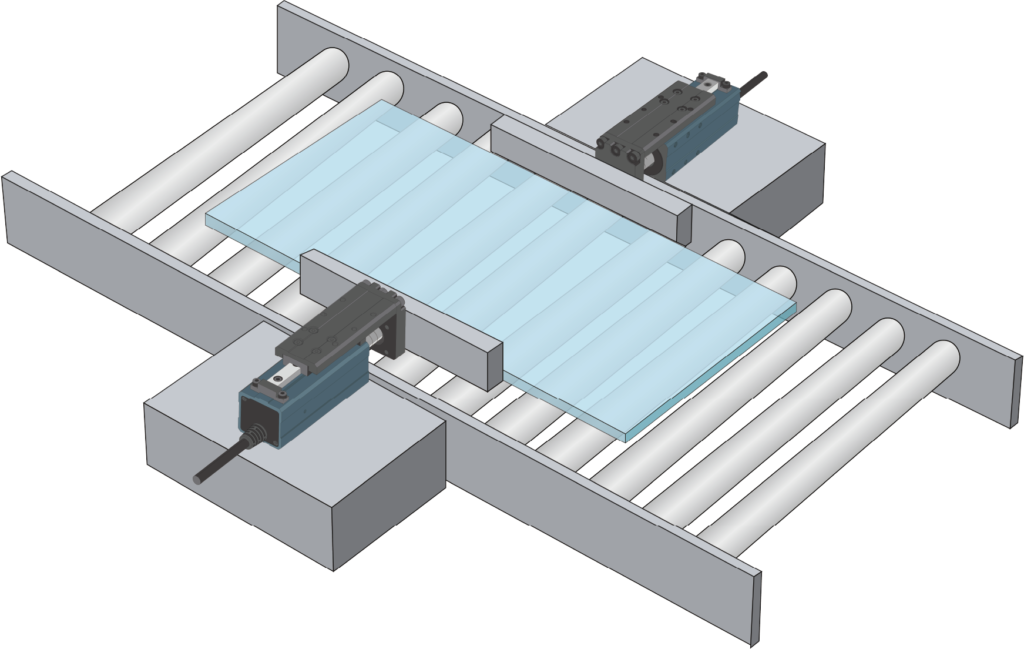

- Panel Industry

The panel is a kind of thin glass sheet which is easy to damage and the surface is extremely flat. Through the precise alignment and precise force control of MCE electric cylinder, the positioning correction, pushing and clamping functions are completed for the panel on the production line to ensure that the workpiece enters the next process in a flat and orderly manner. The solution is also suitable for correcting and sorting of different sizes of workpieces in the food and pharmaceutical industries.

Positioning correction, pushing and clamping

- Mechanical processing industry

In the automatic stamping production line, the MCE series miniature servo electric cylinder can be used to push in and transport large weight processing materials to the stamping machine. The maximum handling weight in the horizontal direction can reach 15kg and the maximum thrust force is 200N, which can effectively replace manual handling and ensure the accuracy of workpiece processing, while reducing the risk of worker accidents and improving production efficiency.

Pressure-bearing loading

Pressure-bearing loading