At present, the new crown epidemic is still spreading around the world, and national nucleic acid screening has become the primary checkpoint for epidemic prevention and control. Under the huge demand for quarantine operations in my country, nucleic acid sampling robots came into being. In July this year, the second-generation dual-arm composite collaborative robot “Pengcheng Qinggeng” integrated with DH-Robotics’s PGE series electric grippers was officially unveiled at the Shenzhen Civic Center. This is the world’s first full-process automated nasopharyngeal swab sampling robot.

Video source: Shenzhen Luohu Hospital Group

The nucleic acid sampling robot can imitate the actions of senior nurses for nucleic acid sampling. In the early stage of sampling, the robot cooperated with DH-Robotics’s PGE electric gripper to open and close the sampling tube, scan the code, and grasp and calibrate the nasopharyngeal swab. During the sampling process, the PGE electric claw based on Dahuan’s precision force control technology can perform gentle, safe, accurate and fast nucleic acid sampling of nasopharyngeal swabs for users, and seal the samples.

According to official data, as of July 16, 180 subjects have completed preclinical use under the guidance of medical ethics, and the relevant samples collected have been sent to the medical testing center as required, and the quality of the samples meets the testing requirements. According to the questionnaire, more than 90% of the subjects reported that the robot collection of nasopharyngeal swabs was gentle, and the discomfort was less than that collected by manual medical care.

In this application, the DH-Robotics’s electric gripper is equipped with a flexible “smart hand”. Its fine perception and flexible operation achieve standardized and standardized sampling quality, realize fully autonomous sampling operations, and greatly reduce the burden of medical staff. Collect pressure. Previously, the nucleic acid sampling robot equipped with Dahuan electric claw has been tried in Shanghai, Hubei and other places.

Helping medical nucleic acid detection, electric actuators are promising

In the face of the normalized national nucleic acid screening needs, hundreds of millions of single-sample and mixed-sample test specimen data have flooded into major disease control and tripartite testing centers, and the requirements for the efficiency of testing institutions are getting higher and higher. , and nucleic acid robots can effectively complete the sampling work in the early stage of quarantine work, improving the overall sampling and testing efficiency.

At present, medical institutions in various places are also rapidly establishing high-throughput detection capabilities for the new coronavirus. However, due to the fact that in the process of sample processing, their automated detection operations have not been fully popularized. Not only is the process time-consuming and the operation is cumbersome, but also during the process of medical staff frequently contacting samples It also greatly increases the risk of viral infection.

Therefore, in order to improve detection efficiency and reduce human errors, it is urgent to improve the high-pass quantification and automation of detection by major disease control and tripartite testing centers. The adoption of new detection methods such as fully automatic detection equipment has become a rigid need.

Facing the needs of nucleic acid detection automation in the medical field, DH-Robotics, based on its own core technology of precision motion control, provides a series of intelligent grasping and precision motion products with high hygiene standards, high quality and high technology to assist medical staff in completing nucleic acid. Inspection of the whole process operation, providing overall inspection efficiency.

Compared with traditional pneumatic actuators, the air gripper needs to be connected to an external air source, with low integration and high noise, which cannot meet the cleanliness requirements of medical scenes. In addition, since the detection of medical samples needs to be handled with care, there are certain requirements for the grasping accuracy and stability of the execution components, and the pneumatic components cannot achieve precise force control. In the face of sudden power failure, the reagent bottle will be dropped, overturned or broken, and there are high uncertainties in the pneumatic solution.

Dahuan electric gripper adopts the principle of electric drive control, the product is silent during operation, and no air source is required, which can ensure the cleanliness of the sample and the environment. For the testing laboratory/hospital environment, the relative advantage of the electric gripper is greater and more convenient. meet its application requirements.

At the same time, based on the self-developed precision force control and integrated integration technology, DH-Robotics’s electric claw has the advantages of compact size, easy to use, high precision, strong stability, and beautiful design. Among them, the RGI series rotary electric gripper standardizes the realization of functions, integrates drive and control, saves the non-standard design cost of using motor + air gripper + transmission device, is more standardized and more stable, and enables equipment manufacturers to quickly develop and deploy equipment to effectively meet the needs of Medical automation requires the accuracy and efficiency of tasks such as opening and closing lids, handling, and loading and unloading. In addition, in the era of nucleic acid detection big data, DH-Robotics’s electric gripper can feedback the grasping status in real time based on the data generated by the current, which is convenient for data analysis and equipment management.

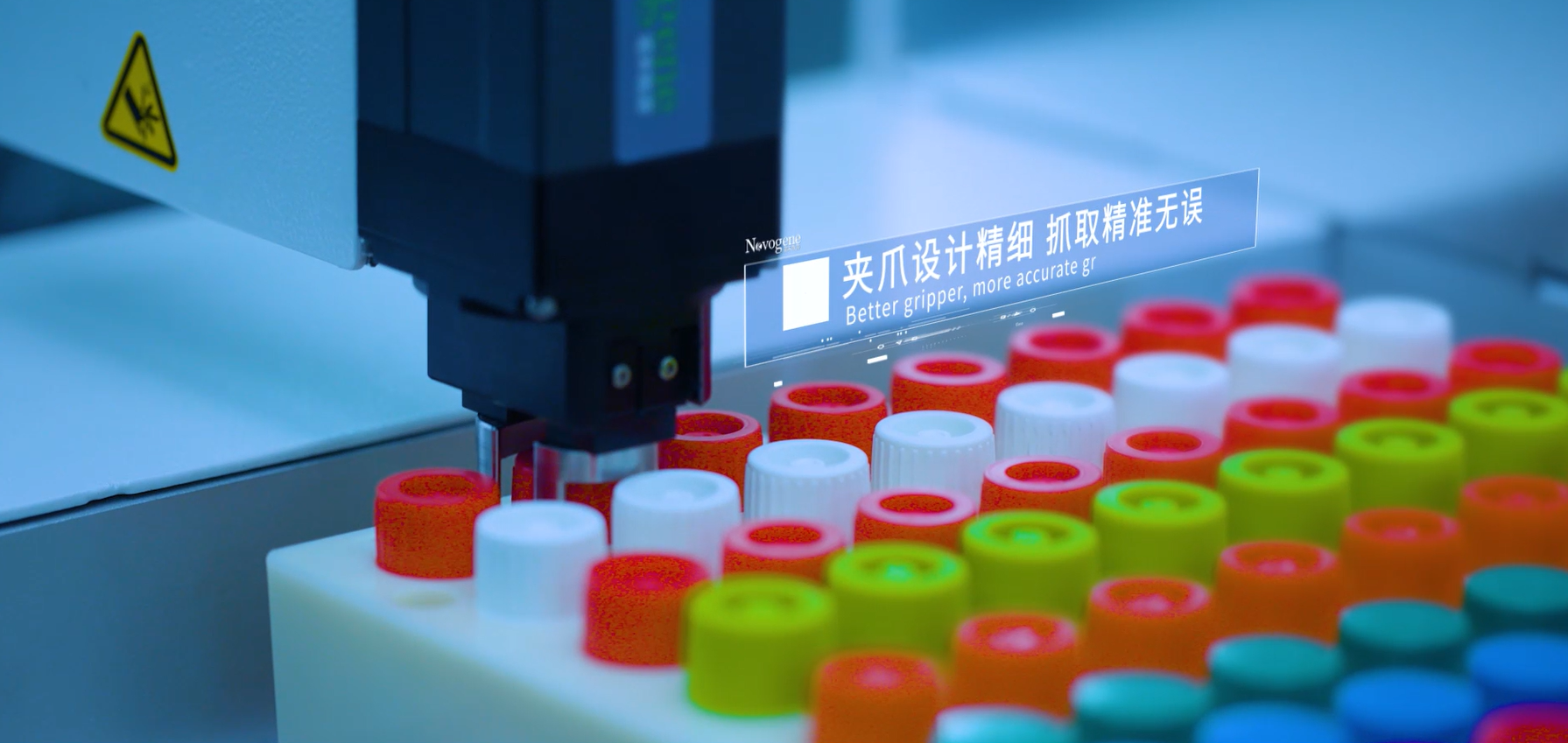

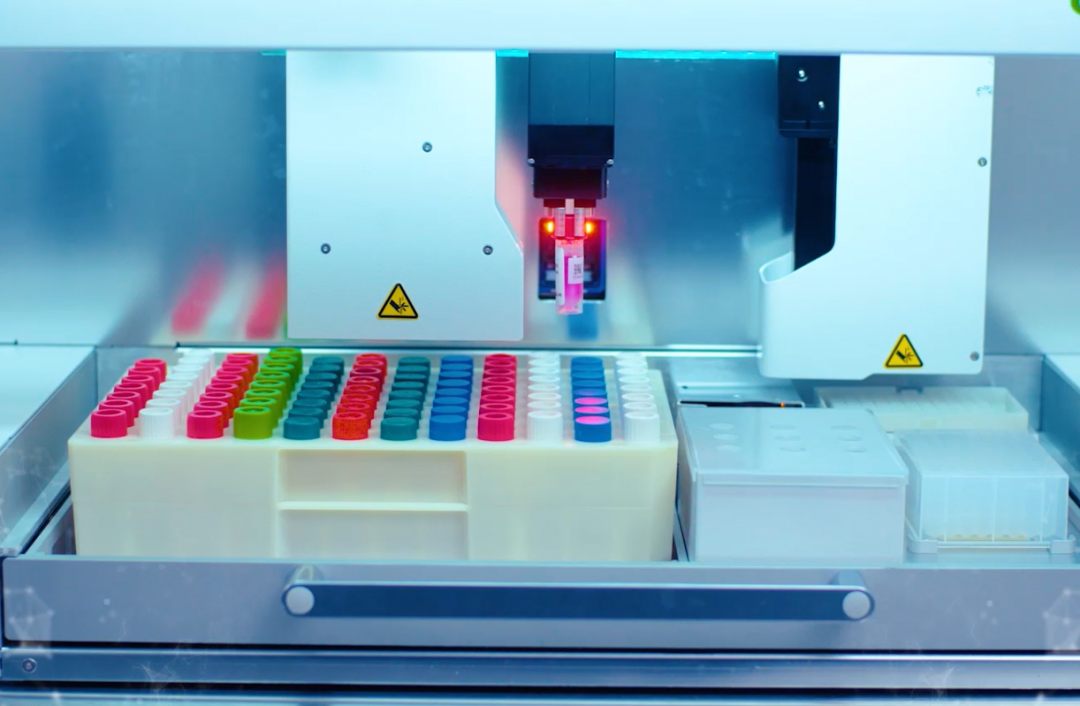

For example, in the automatic cup processing system for nucleic acid sample detection, Dahuan Robot RGI rotary electric claw can accurately, stably and efficiently complete the grasping of sample test tubes, automatic code scanning, information input, automatic cap opening, and then extraction. Throat swab samples containing positive samples are transferred to the deep-well plate, and a series of actions of automatically closing the cap and recovering the original cap of the original tube are completed. This is the most complicated and dangerous part to be handled in automated sample testing. The working environment is in the whole process. The airtight negative pressure state ensures the cleanliness of the sample and the accuracy of the test results.

After the sample cup processing is completed, the robot combination of “robot + Dahuan electric claw + vision” will be used to grasp, load and unload and unmanned handling of the 96-well plate kit that has been tested. During this process, DH-Robotics’s electric claw grasps the kits in turn and puts them into 96-well plates, and then transfers the filled 96-well plates to the storage bin, or transports the processed sample boxes to the testing equipment. , to stabilize the grip to ensure the integrity of the sample during transportation.

In the fully automated unattended multi-function sample preparation station, the six-axis robotic arm is equipped with Dahuan robot AG series/PGC series electric grippers to complete complex tasks such as loading and unloading, opening and closing lids, and handling. , the sample is transported in several modules of sample storage, liquid processing, vibration extraction, and centrifugal separation to ensure high-throughput, fully automatic, accurate and safe sample preparation.

Through the above application cases, DH-Robotics’s electric gripper mainly completes operations such as grasping, rotating and opening and closing the cover, handling, loading and unloading, etc. Behind this seemingly “simple” work, it plays a pivotal role and is an effective boost to medical treatment. A weapon for the industry to realize automation and intelligent processes.

Starting from the local area to meet the needs of automation transformation

Since the outbreak of the epidemic, COVID-19 testing has gradually become a hot big blue ocean market. Data shows that the growth rate of China’s nucleic acid testing market has been 18%-19% in the past three years. The growth rate of China’s nucleic acid testing market leads the world. By 2021, China’s nucleic acid testing market The scale of the testing industry rose to 13.2 billion yuan. It is expected that the market size will further grow to 14.6 billion yuan in 2022.

In the short term, epidemics in various regions have appeared one after another, and the demand for normalized nucleic acid testing will not disappear in the short term. The response speed should be improved, and the testing time should be shortened. Temporary addition of manpower is not a long-term solution, and the medical industry needs more automation transformation. Urgent, and this requires finding automated solutions for some key steps.

At present, the main problems that the medical device industry needs to solve include: small batches and multiple varieties, high labor costs, production equipment that cannot keep up with market development needs, different employee skills, low efficiency, delayed delivery, fierce market competition, and backward marketing models. .

Based on years of accumulation in the field of executive components, Dahuan Robot can provide standardized and intelligent electric executive components for the medical industry from a local perspective, perform repetitive and tedious job substitutions, and improve the level of process technology, so as to improve production efficiency and reduce costs. cost purpose.

Up to now, DH-Robotics has built an electric gripper matrix of 0.8~300 N. For medical scene applications, DH-Robotics is the first to launch the RGI series of rotary grippers with integrated design of dual-servo, and the RGD series of direct-drive rotary electric grippers. series, its compact size, the minimum length of the entire component is only 15cm, the space saving is far more than 50%, and the full cycle cost is reduced by 30% compared with the pneumatic solution, which can realize the multi-product matrix combination application, and can achieve ten million maintenance-free times. , with the intelligent feedback function of grab/drop, making the production line more stable and efficient.

Next, DH-Robotics will continue to deepen its understanding of more industries and application scenarios, dig deep into the automation transformation needs of customers in various industries, provide intelligent execution components that meet customer needs, and create greater added value for customers.

If you want to know more about the application of DH-Robotics products in the medical industry, please contact us.