Industry Applications

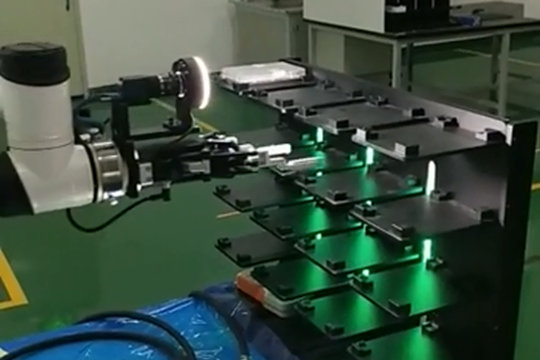

The global manufacturing industry is gradually entering the era of high-end intelligence. There is an increasingly demand on automation, informatization, intelligence, and energy saving. Due to the continuous development of the industry, cost-effective precision motion and smart assembly have become the primary target for the development of smart manufacturing in various industries.

- Medical automation

- Electronics

- Automotive

- Automation

- Machining

- Robot New Retail

- Education Research

- New energy

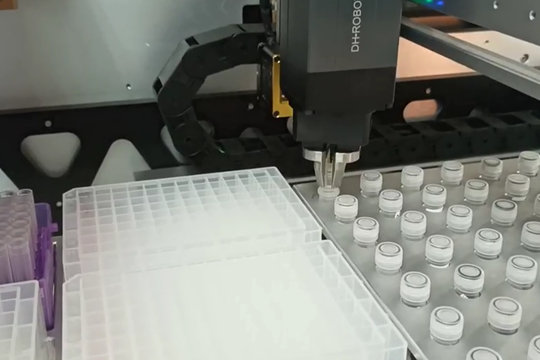

96-well plate storage and handling

The unmanned laboratory is not only embodied in the sample preparation link. Through the combination of “AGV + Six-axis Robot + Electric Gripper + 3D vision”, the 96-well plate reagent kit handling task after the sample is divided into cups can also be unmanned. DH-Robotics electric grippers can complete the task of picking and unloading materials, transfer the 96-well plate to the storage bin, or transport the processed sample box to the testing equipment to stabilize the grip and ensure the safety of the sample during transportation.

Application Products

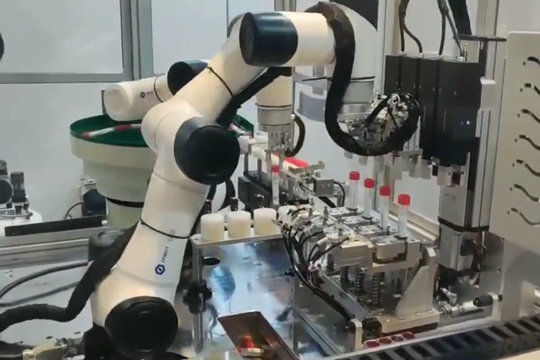

Laboratory automation applications

The combination of “DH-Robotics Electric Gripper + Robot Arm” could complete the entire process application of small laboratory automation on the desktop. From gripping, weighing, liquid withdrawal, closing the lid to returning to the original position, the whole process is dominated by electric gripper and mechanical arm, which can realize completely unmanned operation.

Application Products

Multifunctional sample preparation station

The multi-functional sample preparation workstation built by the six-axis manipulator platform can realize fully automatic unattended sample preparation. DH-Robotics AG series/PGC series electric grippers can complete complex tasks such as loading and unloading, opening and closing lids, and transportation. The samples are transported in the sample bin, liquid handling, shaking extraction, and centrifugal separation modules to ensure high sample preparation. Throughput, full automation, accuracy, and safety.

Application Products

Unmanned new Coronavirus detection

More possibilities for unmanned Coronavirus detection and throat swab sampling: The solution is AGV with two RGI rotating grippers and one PGE parallel electric gripper to complete the collection of collectors, sampling, test tube opening, storing samples, and closing lids , Disinfection and all the above processes. No human intervention is required during the whole process.

Application Products

Throat swab sampling robot

At present, various emergencies have higher requirements for nucleic acid testing organizations. Chinese Government recently notified the requirement to “ensure that all inspections should be completed within 2 days if the number of inspectors is less than 5 million, and all inspections should be completed within 3 days if the number of inspections is greater than 5 million.” This is undoubtedly a huge challenge in terms of speed and safety.

The throat swab sampling robot with DH-Robotics PGE series gripper can complete the sampling step independently without medical staff, and the results can be obtained in as fast as 45 minutes. According to the feedback from the subjects, the robot moves gently and has a good experience. It can be used as an aid to manual detection, improving detection efficiency and saving manpower.

Application Products

Multi-channel nucleic acid virus divider

The dimension of RGI series is only 50×50 mm with a slender structure that can support the side-by-side installation and operation of multiple grippers in a limited space. Compared with a single-channel device, the multi-channel nucleic acid virus beaker can support simultaneous processing of 2 or 4 sets of samples, which is more efficient.

Application Products

Nucleic Acid Virus Cupping Apparatus

The sub-cup process transplants the scattered reagents into the reagent kits for batch processing and testing (24, 48, 96-well plates) which meet the international standards. In this process, the application of electric grippers can maintain the cleanliness of the kit and samples to the greatest extent.

The virus tube was gripped and rotated for scanning the sampling information.

Application Products

Automated cup processing system

The automatic sub-cup processing system, through ABB’s Scara robotic arm and DH-Robotics electric gripper, can automatically complete the operation of sample tube opening, scanning, information entry, pipetting, turning plate, and closing lid. The whole process is in a closed negative pressure state to ensure that the sample is clean and free from contamination.

Application Products

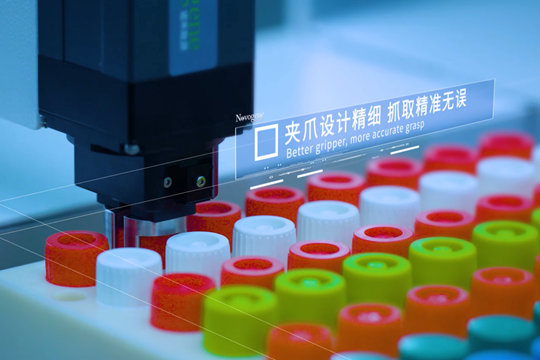

Multi-channel test tube opening and closing lid

The medical industry often involves the processing of large quantities of samples, and more efficient solutions are needed to meet this challenge. The RGI series has a length and width of only 50×50 mm and a slender structure. It can support the side-by-side installation and operation of multiple grippers in a narrow space. Therefore, it can complete the opening and closing tasks of multiple test tubes at one time and improve efficiency.

Application Products

Test tube opening and closing lid

Opening and closing the lid of the test tube is the most common standard task in the medical industry, and the needs of sample testing, preparation, and cupping are all involved. The DH-Robotics RGI series servo rotating electric gripper can complete grasping and infinite rotation tasks on the same gripper, meeting the requirements of the medical automation field for the accuracy, efficiency, cleanliness and aesthetics of the opening and closing tasks.

All products of DH-Robotics electric grippers have obtained CE, FCC, and RoHS certifications.