Intelligent manufacturing upgrade, how to change the transportation system?

Since the emergence of the 18th century, the belt and chain conveyor line has been the “elder” in the factory. However, with the gradual rise of manufacturing upgrades and changes and smart factories, these traditional equipment are gradually unable to keep up with the current pace of production.

What’s the solution?

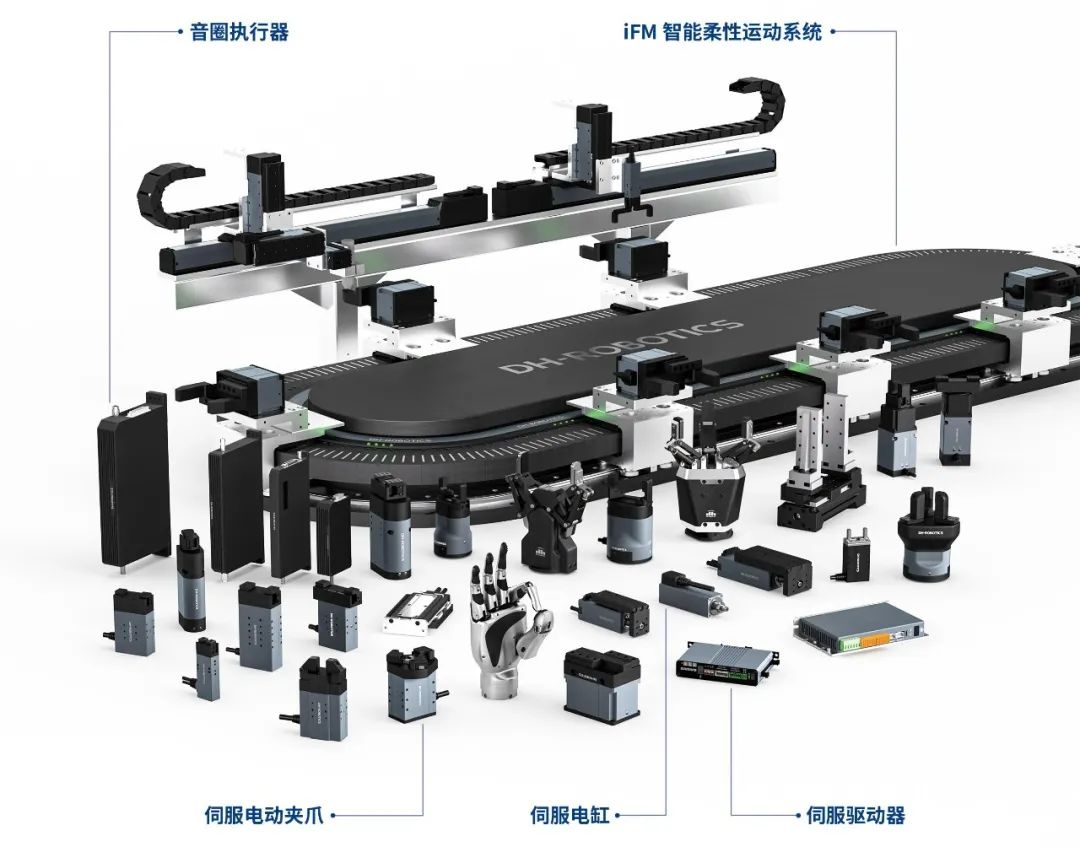

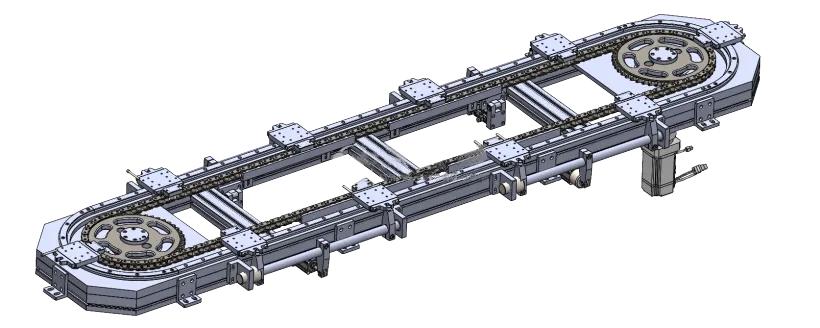

Breaking through the traditional transmission structure such as belt and chain, DH-Robotics has built the iFM intelligent flexible motion system, and innovatively adopted magnetic levitation technology to achieve contact-free transmission, which is more flexible, intelligent and modular, and perfectly fits the modern production needs.

Today, we invited the product manager of DH-Robotics to decode iFM intelligent flexible motion system and talk about how this “maglev black technology” subverts tradition, redefines smart factories, and taps more innovative possibilities for industrial automation.

01 From 0 to 100

–R&d story–

Q: Why did you decide to develop iFM Intelligent Flexible Motion System?

A: In 2019, we started to focus on this direction. We have found that customers are increasingly demanding modular, efficient and easy to maintain transport solutions, and traditional transport lines have been unable to meet market demand. Under comprehensive consideration, in 2021, we combined with our own technology accumulation in the field of precision force control and electric actuators, decided to create a more advanced conveying solution that can meet the needs of different industries, which is the original intention of developing iFM intelligent flexible motion system.

Q: How to apply the existing technology accumulation of DH-Robotics in the development of iFM series?

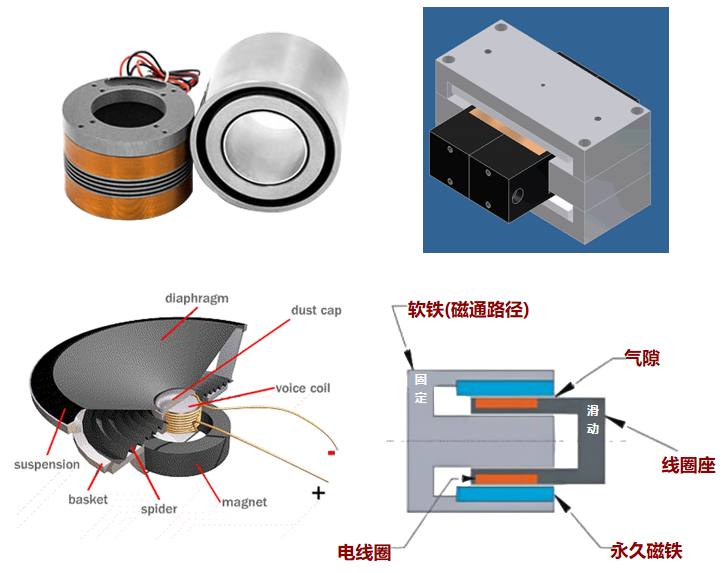

A: The development of iFM intelligent flexible motion system is inseparable from DH-Robotics’ deep technical accumulation and product development experience in the field of intelligent electric actuators.

The system of intelligent electric actuators is strong, and the technical architecture is hierarchical, from the bottom motor and encoder, to the middle drive control, and then to the upper user application, each layer has our technical precipitation. Whether it is a magnetic levitation conveyor system, an electric actuator, or a robot-related product, the hierarchical architecture has a certain degree of commonality. Based on this, we can quickly realize the transformation from concept to product, shorten the development cycle, and ensure the stability and high performance of the product.

Q: What challenges did the team face during the development process?

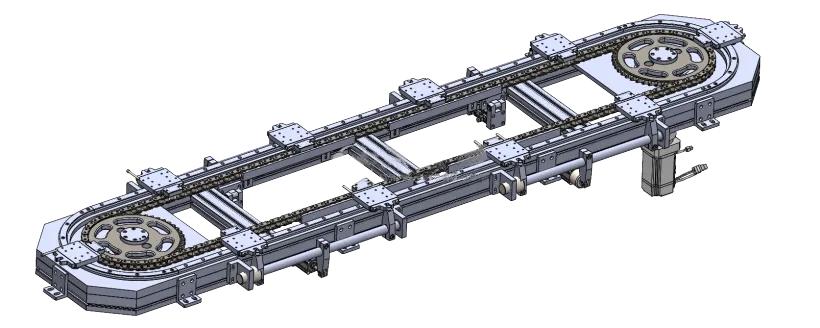

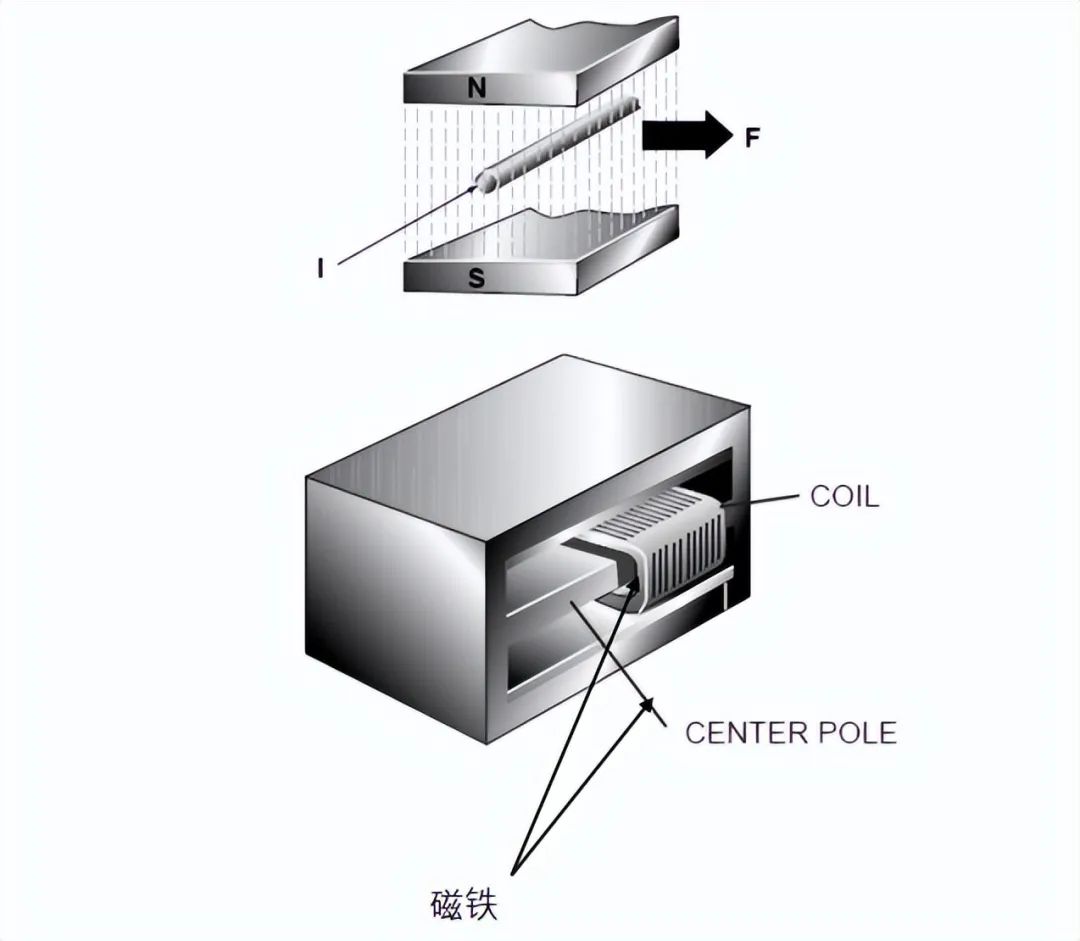

A: There are certainly challenges. Modular design and flexible configuration structure are the most critical characteristics of iFM intelligent flexible motion system, but also the development challenge.From the perspective of working principle, iFM intelligent flexible motion system consists of a stator module to form a moving track, and a moving submodule moves on the moving track. The stator module can be combined and spliced according to the requirements of the station and the scene. The stator module is connected to the power supply and the controller, and the motion planning of the actuator is completed by the controller, which can control the motion of the specific actuator.Conventional products are multi-actor and multi-stator matching, and intelligent flexible motion system is multi-actor and multi-stator series each other, in order to switch between multiple motors in real time, and at the same time to ensure the accuracy of different movers to move to the same position, from a technical point of view, it is difficult to do a lot of testing and development, real-time movement, switching, stationarity.

The key to solving this problem lies in software and algorithms. DH-Robotics has developed algorithms and software for actuators, magnetic encoders, etc., which can effectively compensate the precision errors caused by the switching motion between the multi-actor and multi-stator.

Q:Is there constant communication with the client during development?

A: At all times, making products needs to stay connected to the market. In the early days, DH-Robotics conducted market research visits for a period of time, including collecting the needs of customers, and conducted research on 3C electronics, lithium battery, photovoltaic, medical, food packaging and other industries. The survey found that the requirements for conveying systems in different industries vary greatly. For example:

3C electronics: mainly with light load (0-10kg), high requirements for equipment volume and precision;

Lithium industry: large load (up to 50kg+), requiring high speed (2m/s), high precision;Medical/cosmetics/food packaging industry: strict requirements for cleanliness and IP protection level.Based on these needs, DH-Robotics first develops basic products for specific industry scenarios, and has the ability to “flexibly” meet the needs of different industries.

The key is to maintain the “flexible and modular” assembly capability inside the DH-Robotics.

02 The LEGO Master of Industrial Automation

–Handle complexity and change with ease–

Q: What are the motion characteristics of iFM intelligent flexible motion system?

A: iFM intelligent flexible motion system brings a wider application possibility for intelligent manufacturing

· Modular design, flexible configuration

The iFM Intelligent Flexible Motion system features an independent modular design that supports straight, arc and multiple track layouts. Combined with a variety of configuration forms, such as flat, vertical and flip layout, can be combined according to demand, fast splicing, easy expansion and transformation, to meet the complex production needs of multiple industries. Production line iterative combination only needs to be reassembled, and the cost is lower.

· High thrust density, large load

· High thrust density, large load

With the world’s leading speed, the maximum speed can reach 4m/s, the maximum acceleration can reach 4G. Repeated positioning accuracy (±5μm). Equipped with self-developed absolute encoder, no need for secondary positioning. The super-strong double-sided drive system provides high unit thrust density, flexible splicing of movable magnetic groups, and smooth load bearing of more than 50kg, ensuring efficient and accurate industrial applications.

· Zero wear, low maintenance

· Zero wear, low maintenance

Only guide rail contact, no mechanical friction, effectively reduce maintenance costs, while meeting the needs of high cleanliness production environment. Vibration suppression technology ensures accurate positioning during high-speed movement or emergency stops, improving production stability.

· Intelligent debugging, simplify operation and maintenance

· Intelligent debugging, simplify operation and maintenance

The visual upper computer debugging software independently developed by DH-Robotics. adopts graphical configuration and simulation technology to greatly reduce the difficulty of operation, improve the production emergency response ability, and bring more efficient and intelligent use experience for enterprises.

Q:Is customization supported?

A: Of course, the orders received so far are almost all customized. Relying on the perfect technical system, on the basis of the two series of ring line iFM-L1 series and connection line iFM-T1 series, we can customize the combination according to the actual application scenario requirements of customers.

Taking the 3C industry as an example, the 3C industry chain is very perfect, and the definition and demand for work stations and modules are relatively clear and standardized, which is not difficult for DH-Robotics. Based on years of deep experience in the 3C industry, we can quickly respond to customer needs to complete product customization. For example, customers have clear requirements for station size, load capacity, accuracy, etc., and we can quickly adjust the module configuration. For example, in a headphone inspection project, the customer wanted to optimize cleanliness and motion accuracy, and we adjusted the encoder type and motor configuration to meet the customized needs.

In addition, DH-Robotics also supports contactless power supply scheme to achieve zero friction operation, get rid of the wear problem of traditional towing chain, ensure that the system is constantly powered at any location, and further expand the application boundary, which is suitable for innovative scenarios such as mobile station and intelligent logistics.

Q: What are the sustainability considerations?

A: We have referred to international environmental standards from the beginning of product design, and have done a lot of research in power optimization, motor efficiency, low energy chip and so on. Compared to traditional conveyance methods, the iFM intelligent flexible motion system has lower energy consumption per unit and higher thrust density, which can reduce energy consumption while maintaining high performance.

Q: What other application potential does the iFM series have?

A: In the future, we plan to expand to larger scale applications such as smart factories, automotive manufacturing, semiconductors, and logistics. In particular, the crane hoisting and conveying can be used for automobile assembly, spraying and other processes, and even multi-floor conveying can be achieved, greatly improving the space utilization rate.

03 Embrace AI and explore new heights of value

Q: Will AI technology be introduced more deeply in the future?

A: Sure am. We are exploring the application of AI technology in motion planning, path optimization, intelligent diagnosis and so on. For example, AI optimizes carrier scheduling, reduces beat time, and improves overall production line efficiency. At the same time, combined with the locally deployed AI algorithm, the conveying system has the ability to adapt itself and automatically adjust the optimal operation mode. This is a point of value that we want to create by incorporating AI technology in the future.

If you want to know more about the “iFM Intelligent Flexible Motion System” of DH-Robotics, or have more ideas about industrial automation, please contact us! Follow us to learn more about the story behind black tech.

DH-ROBOTICS

About DH-ROBOTICS

Founded in 2016, DH-ROBOTICS is a high-tech enterprise focused on providing core components for industrial intelligent manufacturing scenarios.

DH-Robotics has been deeply engaged in the field of precision operation and control, filling the gap in the field of precision actuators in China. It has more than 200+ products of servo electric gripper, voice coil actuator, servo electric cylinder, DH-5 smart hand, iFM intelligent flexible motion system, etc. We provide flexible, intelligent and low-carbon electric actuator products and solutions for 3C, new energy, semiconductor and other industries to help customers improve production efficiency and promote intelligent manufacturing and sustainable development.

· High thrust density, large load

· High thrust density, large load

· Zero wear, low maintenance

· Zero wear, low maintenance · Intelligent debugging, simplify operation and maintenance

· Intelligent debugging, simplify operation and maintenance