Some scenes in semiconductor, 3C and other fields have extreme requirements for actuator force control accuracy and response speed, and traditional lead screw schemes or ordinary linear motor schemes are often difficult to meet. At this time, the linear coil actuator becomes a more ideal choice.

What is a linear coil actuator? What is the internal structure and control principle? What are the specific applications? This article will take you deeper.

01 What is a linear coil actuator?

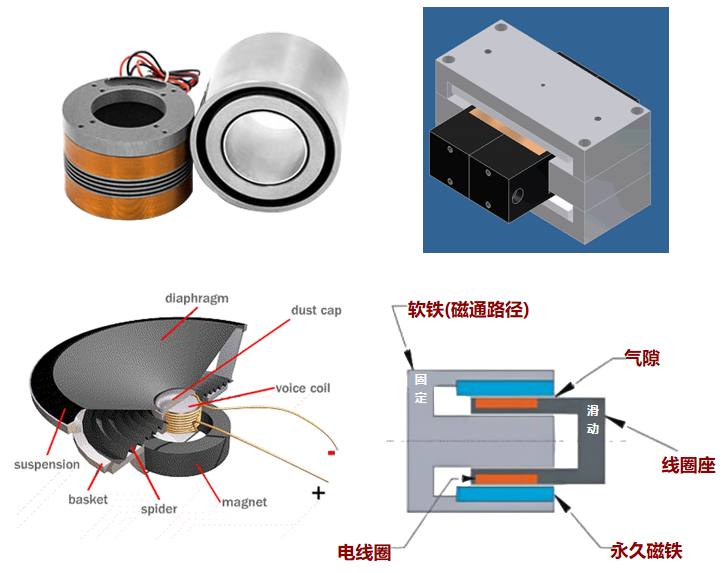

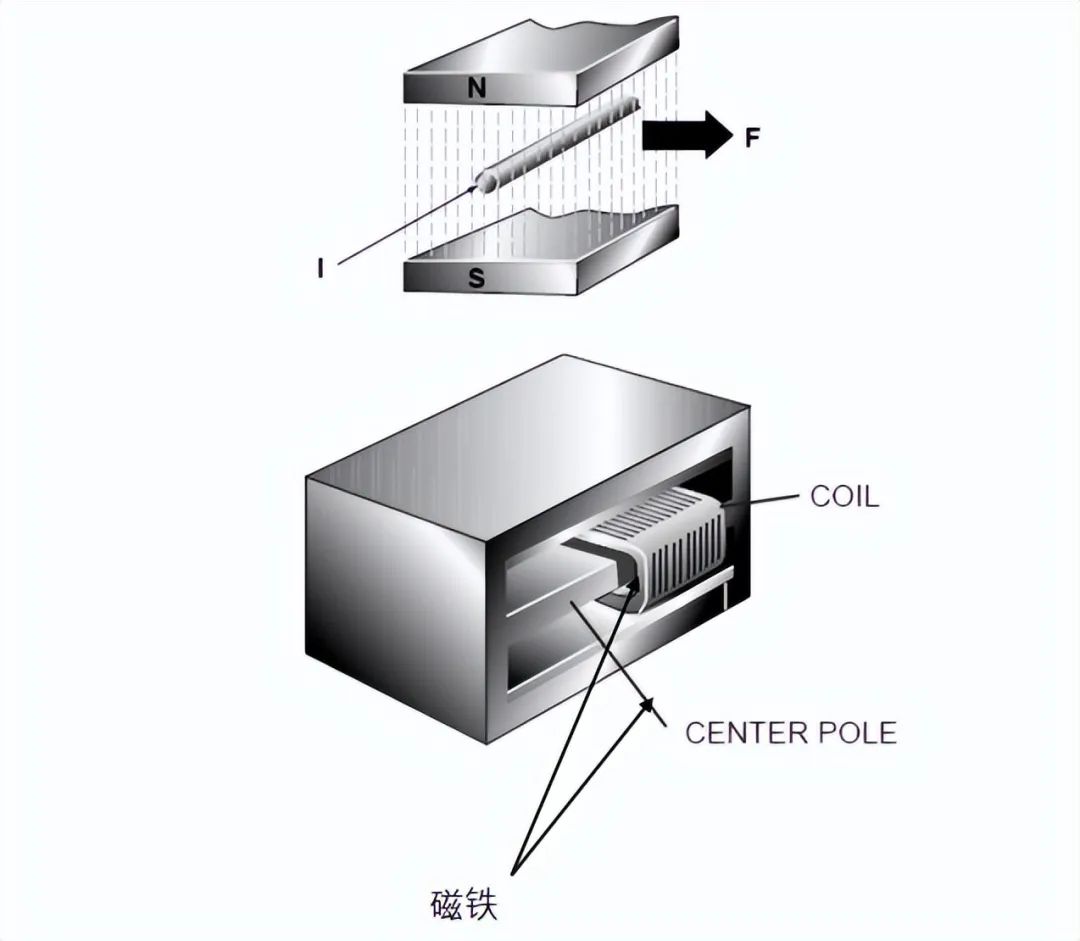

Its basic principle is similar to the permanent magnet application in the loudspeaker (horn), the coil is contained in the magnet shell, as long as the power is supplied to the coil, the electromagnetic force can be generated. Hence the name “voice coil actuator”.

02 Operating principle

If N wires of length L are placed in a magnetic field, the total force on the wires can be expressed as:

03 Interior structure

Permanent magnet: Fixed in position, providing a constant magnetic field that causes the linear coil to produce controlled movement

Linear coil: After energizing, it moves in the magnetic field to generate electromagnetic force and achieve displacement control

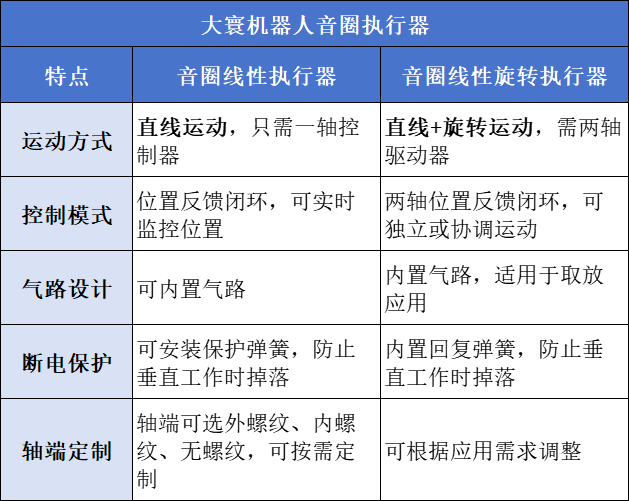

04 Linear VS Linear rotation (compound motion)

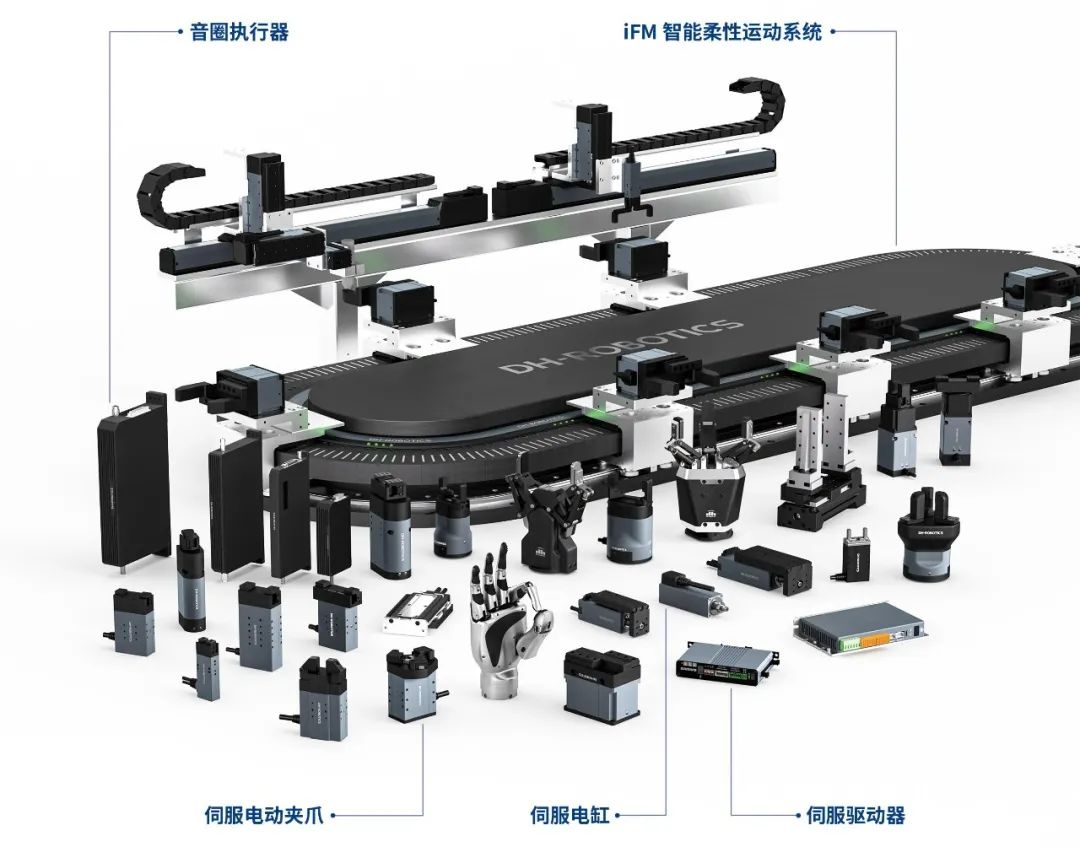

05 DH-Robotics linear coil actuator

The linear coil actuator products of DH-Robotics include “VLA series voice coil linear actuator” and “VLAR series voice coil linear rotary actuator”.

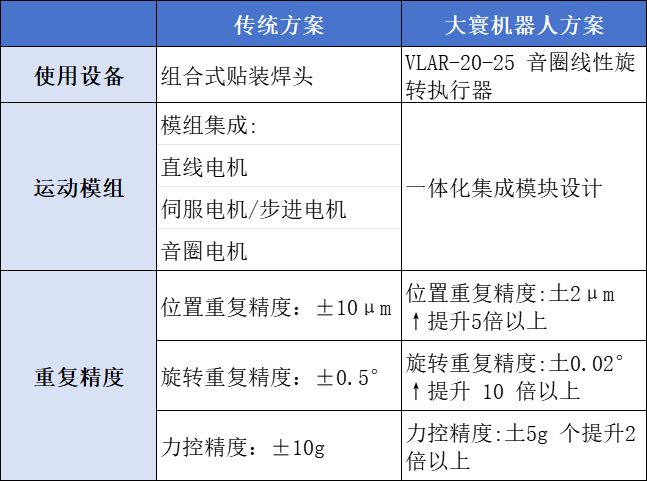

VLA series and VLAR series adopt highly integrated design, thin body, minimum thickness of only 10mm; Can achieve ±5g force control accuracy, some up to ±2g; Repeated positioning accuracy reached ±2μm; Using ultra-high precision encoder, resolution up to micron level, higher optional 0.1μm resolution grating encoder, magnetic encoder resolution of 1μm.

Speed mode | torque mode | position mode

Detect | sort | test | assemble | rotate

Fit | assemble | implant | transfer | snap

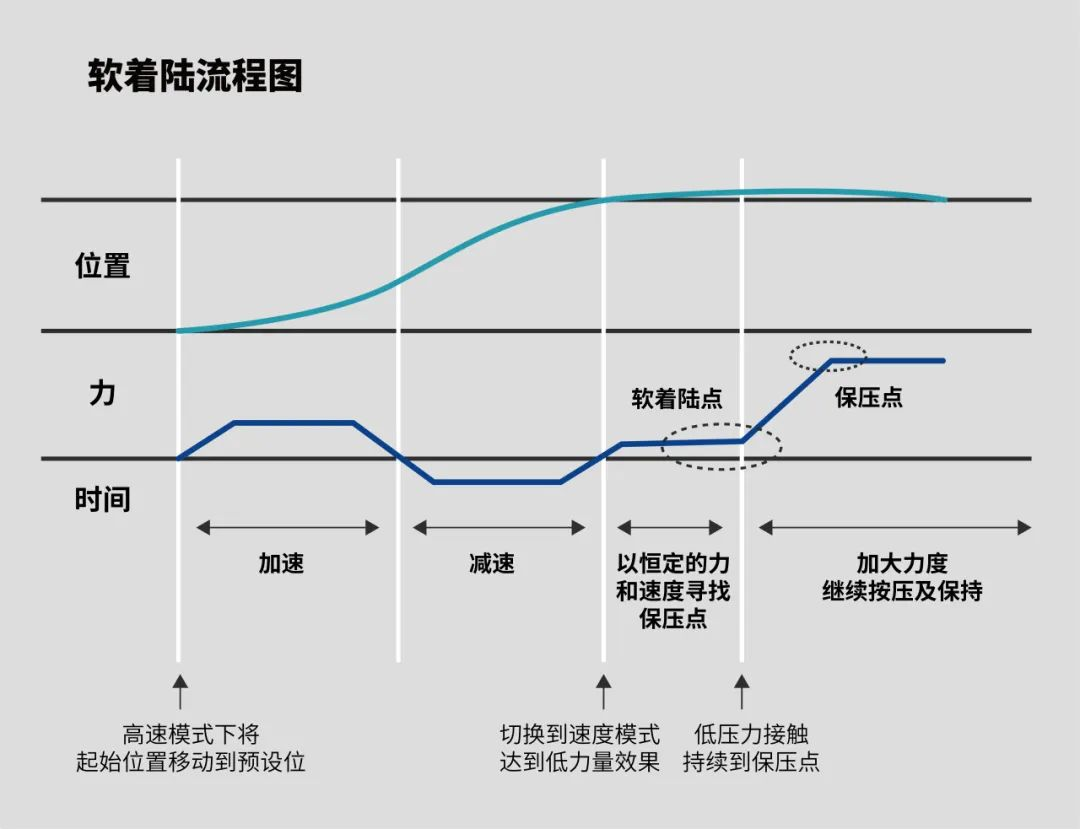

06 Technology Advantage: “Soft landing”

Intelligent “soft landing” means that in the speed mode, the precise control of the linear axis of the actuator, with minimal force, gently contact the surface of the target object, while continuously monitoring the position error, once the contact with the surface of the object, the position error increases to the pre-set value, the motor execution shaft will remain in the surface of the object that position.

The purpose of “soft landing” is to achieve force control during the process of contact between the actuator and the machined part, to prevent device damage or other problems due to pressure.

The “soft landing” process:

2. When approaching the parts, the actuator slows down gradually;

3. Switch from position mode P to speed mode V, and set a small speed value V and current value I; Position errors ΔP and I are continuously monitored.

4. When the preset position error ΔP or current I is reached, the soft landing is completed.

07 DH-Robotics solution VS traditional solution

Taking the chip packaging as an example, when the traditional chip picking mechanism contacts the chip, the speed is too fast, the contact force is too large, and the excessive pressure on the chip causes the chip damage, which greatly affects the yield and efficiency of the chip mounting.

08 Application case

The linear coil actuator of DH-Robotics can provide accurate “straight + rotation” movement, combined with the “soft landing” function, and can touch precision components with ±5g force to protect components from damage, such as chip packaging and camera module assembly.

Used in 3C electronics industry of mobile phones, tablets, smart watch screens and other touch panel detection, keyboard testing, switch detection.

If you want to learn more about DH-Robotics “linear coil actuator”, or have more ideas about industrial automation, please leave a comment!

About DH-Robotics

DH-Robotics has been deeply engaged in the field of precision operation and control, filling the gap in the field of precision actuators in China. It has more than 200+ products of servo electric gripper, linear coil actuator, servo electric cylinder, DH-5 smart hand, iFM intelligent flexible motion system, etc. We provide flexible, intelligent and low-carbon electric actuator products and solutions for 3C, new energy, semiconductor and other industries to help customers improve production efficiency and promote intelligent manufacturing and sustainable development.