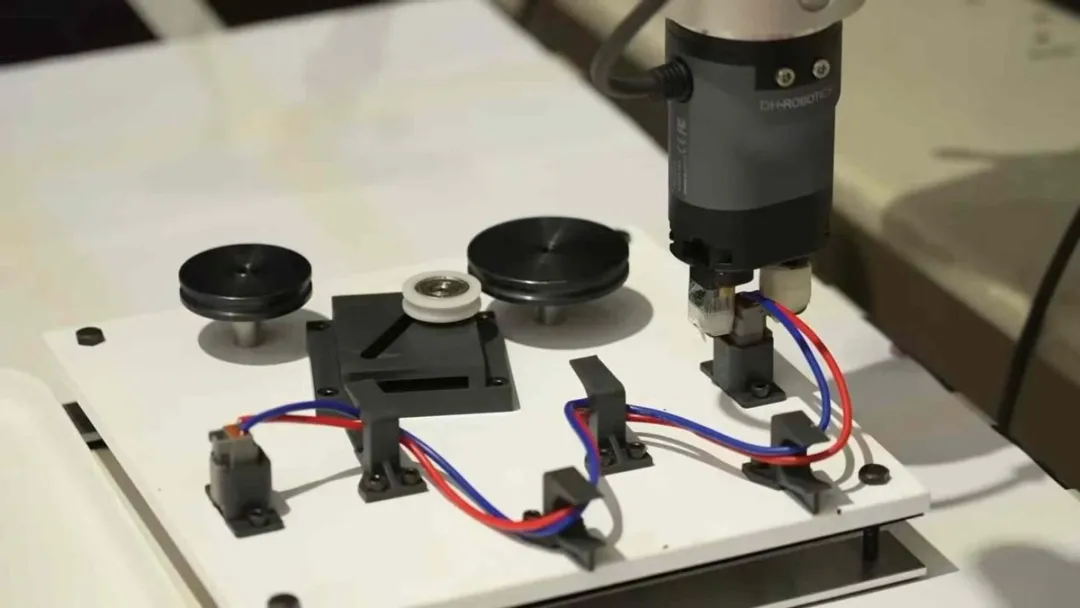

Recently, the Omni-Mani team from the University of Hong Kong, in collaboration with Jinan University Zhuhai Campus, won the first prize in the “Robot Cable Organization and Plug-in Task” track at the “Zhuhai International Agile Manipulation Challenge and Embodied Intelligence Industry Conference.” The Omni-Mani team used DH-Robotics’ self-developed PGC-50-35 collaborative parallel electric gripper, mounted on a collaborative robot arm, to complete the task of organizing and plugging cables in a cluttered environment with flexibility and stability.

About the Omni-Mani Team

The team is led by Dr. Jia Pan, Associate Professor in the Department of Computer Science at the University of Hong Kong and Chief Scientist at Zhuji Power. It includes postdoctoral researchers Dr. Peng Zhou and Dr. Jia-Ming Qi, as well as PhD student Li Zhongxuan. Dr. Pan’s research primarily focuses on machine learning and robotics.

Fine Manipulation of Deformable Objects

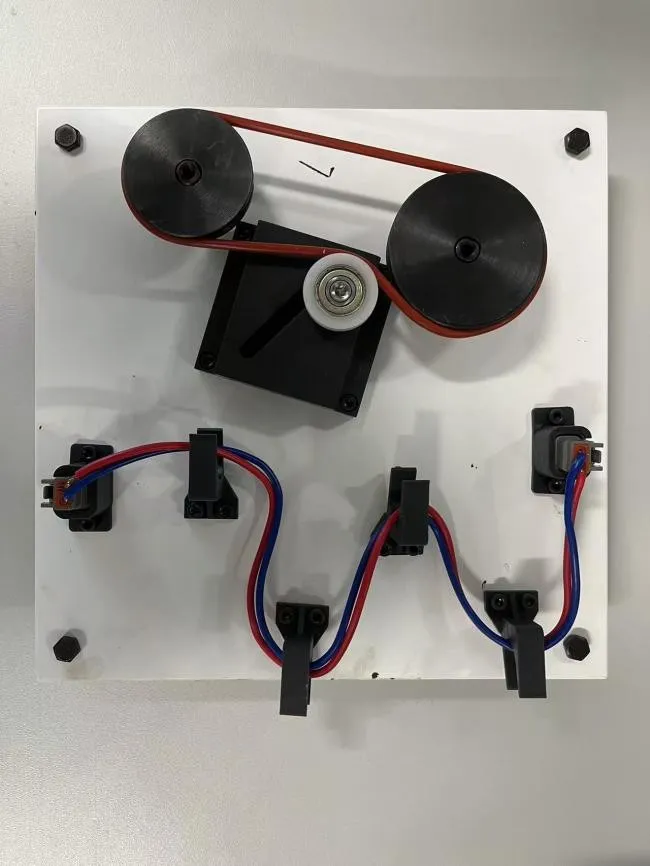

The task of organizing and plugging cables involved four main steps: belt installation, cable installation, belt removal, and cable removal. The key challenge lay in the fine manipulation of deformable objects like belts and cables.

To represent these deformable objects, the Omni-Mani team used a combination of multi-view “SAM + VLM prompts” to estimate the state of the belts and cables during the task. This was further enhanced with a state machine model to plan and transition to the correct action primitives.

Small But Powerful: The Role of the PGC-50-35 Collaborative Gripper

The success of the task heavily relied on DH-Robotics’ PGC-50-35 collaborative electric gripper. The PGC series is designed for collaborative robot applications and is compatible with all mainstream collaborative robot brands, with DH-Robotics’ proprietary plugin for easy control and programming.

The Omni-Mani team chose the PGC-50-35 for its suitability to the task’s requirements. The operational area in the competition task was compact, measuring only 25 cm by 25 cm. To perform multiple tasks in such a small space, the robot needed a gripper that was not only compact but also stable and reliable.

The PGC-50-35 perfectly matched the team’s needs. With a compact design (124mm × 63mm × 63mm) and weighing only 0.5kg, the gripper offers a stroke of 37mm and a gripping force of 15–50N, with repeatability accuracy of ±0.03mm. The PGC-50-35 has undergone extensive real-world testing and has gained high recognition for its stability and reliability.

Looking Ahead: The Future of Automation

DH-Robotics is committed to developing more precise, stable, and reliable electric grippers and other core components for industrial intelligent manufacturing. The company aims to contribute to the industry’s upward development with these innovations.

About DH-Robotics

Founded in 2016, DH-Robotics is a national high-tech enterprise specializing in core components for intelligent manufacturing. Headquartered in Shenzhen, China, DH-Robotics has branches in East, Central, and North China, as well as an overseas operations center. Its service network covers multiple regions worldwide.

DH-Robotics offers three major product series: servo electric grippers, voice coil actuators, and servo cylinders, with over 200 sub-models. In 2024, the company launched new product lines, including the DH-5 Dexterous Hand and the iFM Intelligent Flexible Motion System.

With over 800 end customers across more than 30 countries, DH-Robotics has earned widespread recognition for its stable manufacturing supply chain and comprehensive sales and service network, making it a leader in core components for industrial intelligent manufacturing.

01.jpg)