In today’s fast-paced industrial landscape, precision and repeatability are more important than ever. As automation technology continues to advance, industries like 3C electronics and semiconductors require systems that can handle high-precision tasks with speed and reliability. At DH-Robotics, we understand these demands, which is why our electric rotary grippers are engineered to meet the needs of the most complex automation tasks. Our RGD series of electric rotary grippers offer cutting-edge features designed to maximize production efficiency and improve automation outcomes.

Advancing Automation with Electric Rotary Grippers

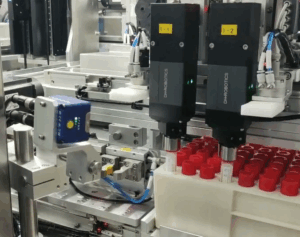

Electric rotary grippers are playing an increasingly critical role in modern manufacturing processes. With industries demanding higher precision for assembly, positioning, and handling tasks, the need for rotary grippers that offer zero backlash and high repeatability is growing. In semiconductor production and 3C electronics assembly, even the smallest errors can lead to significant production delays and costly defects. This is where DH-Robotics comes in. Our grippers provide the stability and accuracy needed to drive high-performance automated systems, offering a seamless integration into existing production lines while ensuring unmatched precision.

Exploring the Features of DH-Robotics’ RGD Series

The RGD series from DH-Robotics is a prime example of our commitment to precision and performance. These electric rotary grippers utilize direct-drive technology, which eliminates backlash—an issue that can affect accuracy and repeatability in many applications. The result? A rotation resolution that reaches an incredible 0.01°, perfect for high-precision tasks in semiconductor production. The rotary gripper also boasts a fast rotation speed of up to 1500° per second, allowing for quick adjustments and real-time precision during assembly and positioning tasks. These features make the gripper ideal for industries that require consistent and accurate movements, from fine-tuning small components to assembling intricate electronic devices.

Enhancing Production Efficiency with DH-Robotics Electric Rotary Grippers

At DH-Robotics, we believe that efficiency is just as important as precision. That’s why the RGD series is designed with an integrated structure that reduces the need for external components, making it both compact and easy to implement. The dual servo system for gripping and rotating is seamlessly integrated with the drive control module, enabling faster response times and smoother operation. Additionally, we offer optional brakes for enhanced control over the gripping and rotating movements, providing more flexibility for various applications. Power-off protection ensures that the gripper remains reliable even in case of power interruptions, further boosting operational stability.

By optimizing our electric rotary grippers’ design, we not only ensure superior precision but also deliver a solution that improves overall production efficiency. DH-Robotics’ innovative control methods make the RGD series a dependable choice for any application requiring high-speed, high-precision movements.

Precision and Efficiency in Automation: DH-Robotics RGD Series

The RGD series from DH-Robotics represents the pinnacle of electric rotary gripper technology. It not only achieves zero backlash, high repeatability, and high-speed rotation, but also features a compact, integrated design. These advantages significantly enhance the performance of automation systems. Whether you’re working with 3C electronics or semiconductor components, our electric rotary grippers provide the precision and efficiency you need to stay ahead in a highly competitive market. With the grippers, achieving unmatched precision and enhancing production efficiency has never been easier.