As an important downstream of intelligent manufacturing equipment, 3C industry is more mature than the overall manufacturing industry after decades of development, and the industry chain is complete. But from the perspective of the coverage rate of production process, the penetration rate of automation and intelligence is only 20-30%. With the faster and faster iteration speed of electronic products, the need for industrial intelligence upgrading is growing.

On August 19th, DH-Robotics attended the 2022 Automation System Integration Application Technology Exchange Conference, hosted by Foxconn Technology Group and sponsored by GG-ROBOT. The event was held in the form of offline + online Foxconn factories. Nearly 30 big shots in the industry shared on the scene, and more than 600 professionals attended this unique technology exchange event.

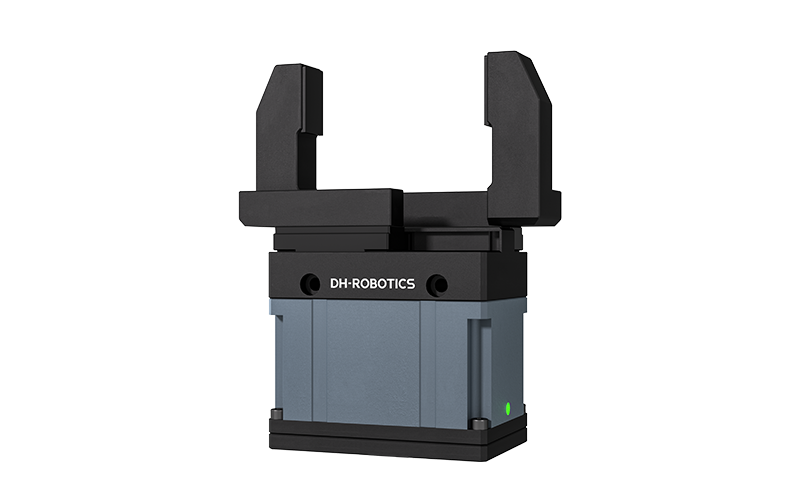

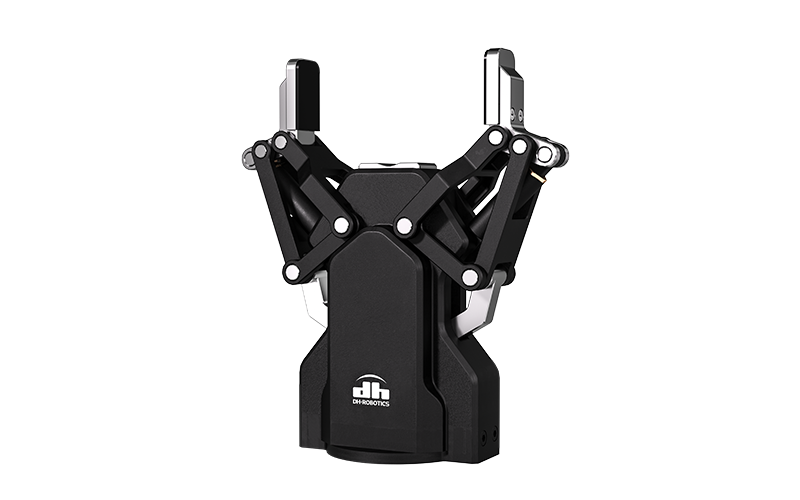

Aiming at the characteristics of large number of parts in 3C products, with small volume, high precision requirement, strong non-standard product attributes, etc., Dahuan Robot focuses on the 3C manufacturing automation requirements, creates diversified intelligent grasping products such as adaptive electric gripper, parallel electric gripper, rotating + clamping electric gripper, three-fingered electric gripper, etc., and forms a unique product characteristics with “precision, intelligence, flexibility, easy-to-use” as the core, which can be well adapted to various scenes such as grasping, detection, sorting, handling, assembly, loading and unloading, rotating, opening and closing the lid, etc., and fully meets the flexibility, electro-motive and intelligence requirements in 3C manufacturing and lean production.

3C Industry Solutions (Part)

-

- Headphone Production

01.jpg)

In the assembly of wireless Bluetooth headphones, because the customer has used the pneumatic clamp, its holding force is unstable, which is easy to damage the surface of the headphones.

In order to improve product yield, the customer chooses the combination of cooperative robotic arm + Six Dimensional force sensor + DH-ROBOTICS PGE-50-26 electric gripper to complete the grasping, rubbing and testing of the earphone workpieces.Based on the precision force control technology developed by DH-ROBOTICS, the PGE electric gripper can reach the force repetition precision of 0.1N. While holding the earphone steadily, it can finish the automatic operation of rubbing and testing efficiently, and further improve the product yield.

img class=”alignnone size-full wp-image-2695″ src=”https://www.dh-robotics.com/wp-content/uploads/2022/08/PGE-50-26.jpg” alt=”” width=”2251″ height=”2348″ />

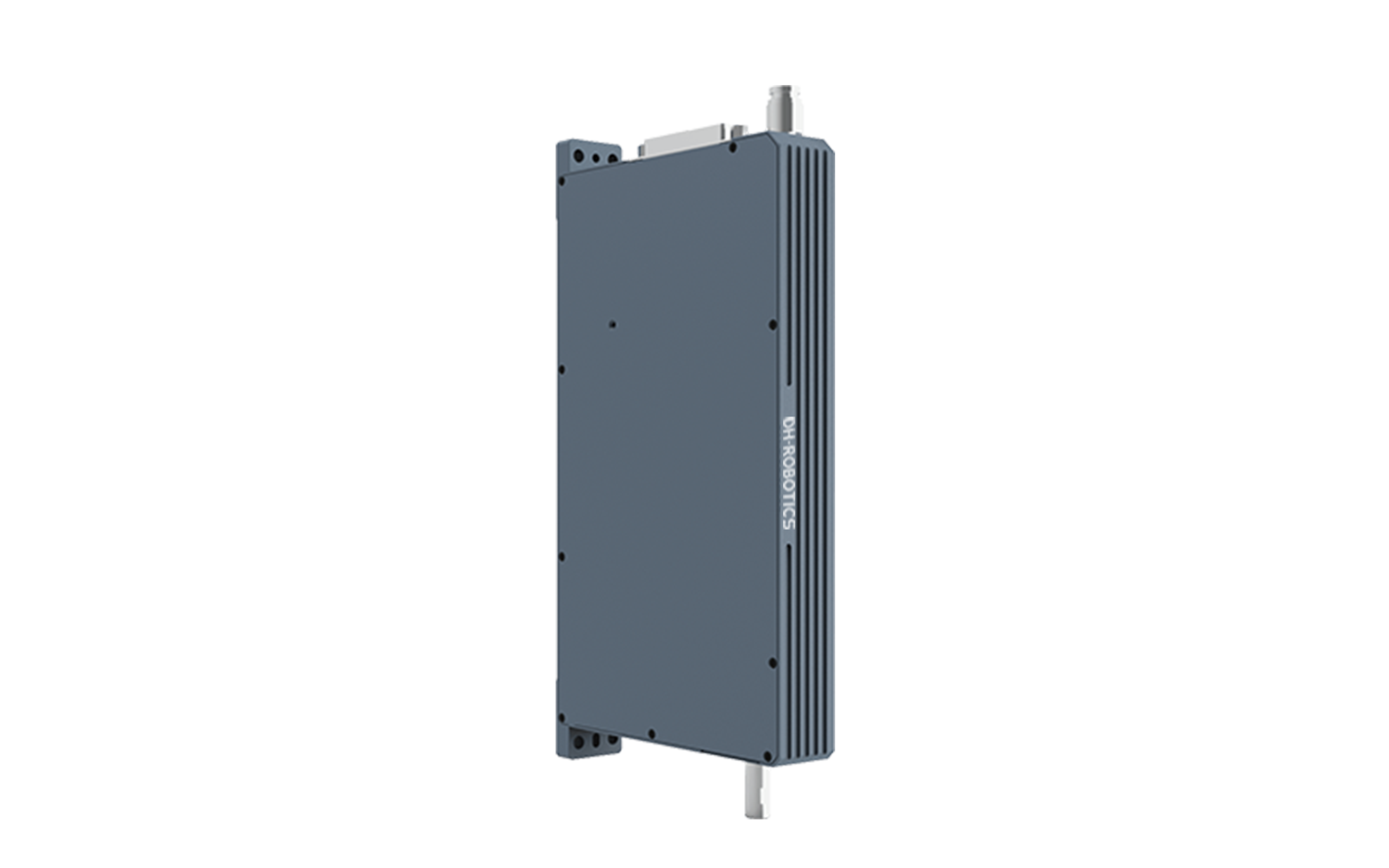

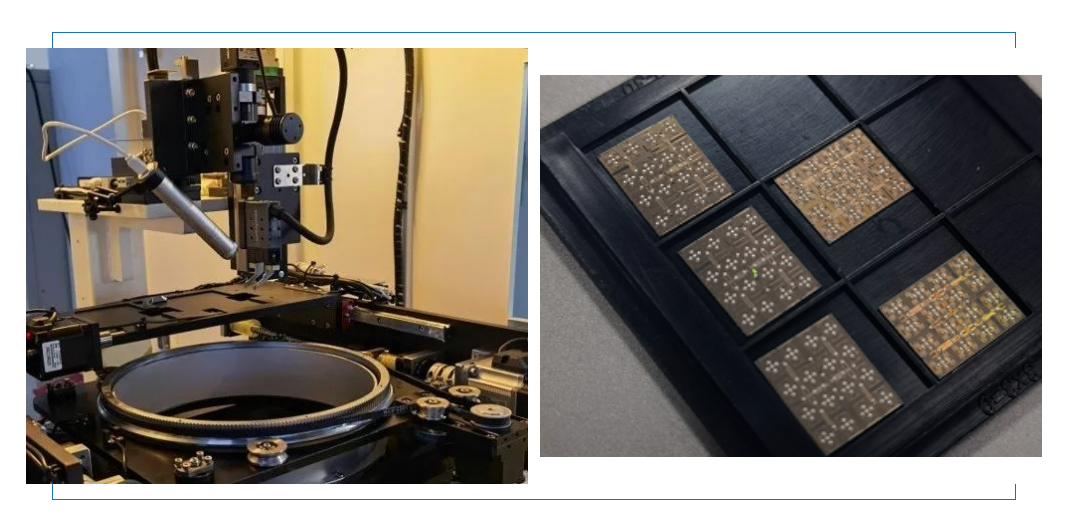

- Chip Clamp Handling

DH-ROBOTICS PGE-2-12 electric gripper is used in the chip handling process of semiconductor wafer sorter to replace the traditional vacuum chuck, which avoids the risk of chip dropping due to insufficient vacuum of the chuck.

In this application, the DH-ROBOTICS PGE-2-12 electric gripper has high precision force control attributes, can steadily grasp the chip such as small workpieces to ensure product yield.

PGE electric gripper has small volume and flexible installation, the thinnest part of the product is only 18mm, so it can be integrated into the automation equipment in narrow space; in addition, according to the program, the electric gripper can realize accurate positioning, easy to pick up and carry, greatly improve the production efficiency of the production line.

- Lens Assembly, Optical Inspection

In the lens inspection link, using the traditional vacuum chuck to clamp the lens for lighting and taking photos will affect the visual inspection effect, and there is a risk of damaging the lens in handling due to the instability of the pneumatic scheme; in the lens assembly link, due to the irregular arc shape of the lens, the lens assembly needs to reach the accuracy of micron class, and to simultaneously complete the dual tasks of clamping and rotating, the clamping force needs to reach 4.5N, and at the same time, the electric gripper needs to realize the function of self-locking when power failure occurs.

In the application of the project, DH-ROBOTICS for customer needs, in the automation equipment integration of PGE parallel electric gripper and RGD direct drive rotary electric gripper combined scheme.PGE-5-26 electric gripper is used to complete the flexible clamping of spectacle lenses with a total length of 26mm, which can directly cover the diameter of spectacle lenses without damaging the spectacle lenses or affecting the testing operation; however, RGD-35-14 electric gripper adopts “clamping and turnover” design, can achieve zero backlash in rotation with a rotation resolution of up to 0.01 ° and completes the assembly operation of spectacle lenses in rotation with high precision.

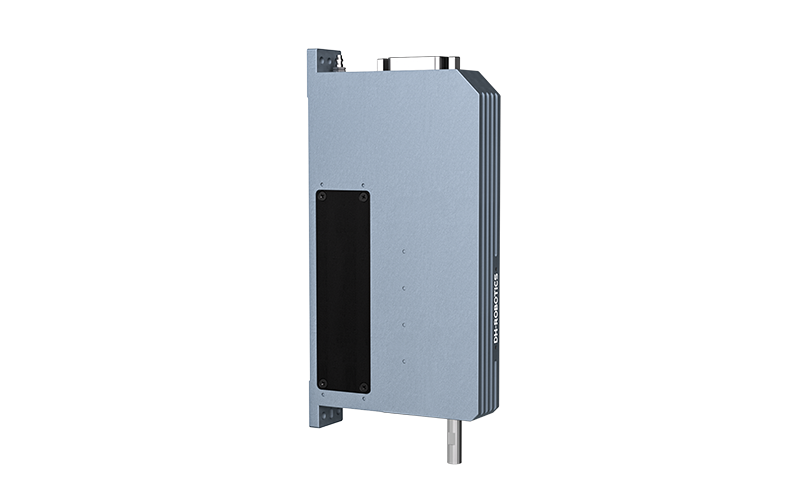

- CNC Replacement Blades

In the process of CNC machining, the customer uses a compound cooperative robot with electric gripper to replace the cutters correspondingly to ensure the simultaneous operation of multiple machining centers and improve the utilization of the equipment.Considering the complex and harsh processing environment, PGI-140-80 electric gripper with high protection grade IP54 is used in the design of DH-ROBOTICS, which effectively ensures the service life of the manipulator.

In this scenario, the composite mobile robot with electric gripper does not need to be equipped with an air compressor, making it easy for the mobile equipment to perform high frequency material change operations. The DH-ROBOTICS PGI electric gripper is compatible with materials of different sizes and weights, and is suitable for CNC loading and unloading applications that require a high degree of protection.

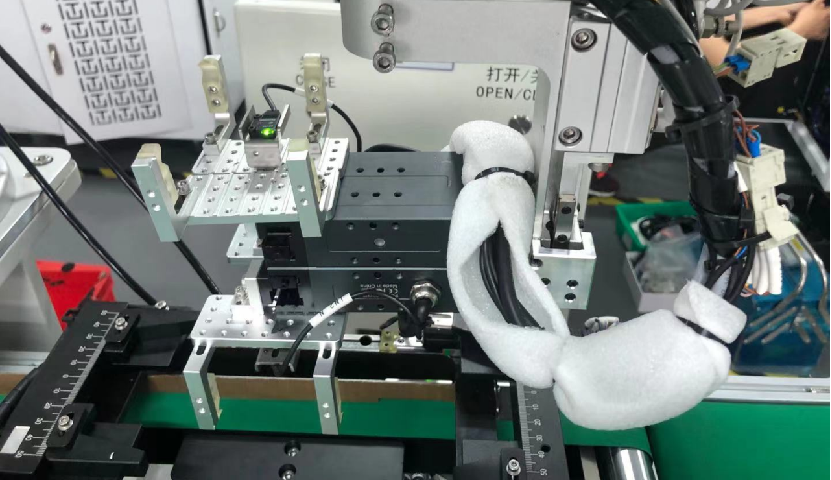

- Mobile Phone Audio Detection, Loading and Unloading, etc.

In the process of mobile phone audio detection, the customer applies electric gripper through the automation equipment integration to complete the mobile phone audio detection, loading and unloading and handling of the finished mobile phone.

For the application of customer scenario, two PGE-50-26 parallel electric gripper of DH-ROBOTICS are selected. The electric gripper has a long stroke and strong compatibility. It can hold mobile phones of different sizes. At the same time, the mobile phone can be tested and loaded without additional sensors.

DH-ROBOTICS electric actuators have won wide market recognition by virtue of their excellent performance in a variety of complex applications.At present, DH-Robotics has become a trusted partner of first-class enterprises in such industries as Foxconn, BYD, Luxshare Precision, Mindray, Lens Technology, Bosch, etc.

Because of the upgrading of consumption and technological innovation, the automation of 3C manufacturing is the trend of the times. DH-Robotics hopes to build high-quality and inexpensive electric actuators, and reach in-depth exchanges with end head companies represented by Foxconn, to jointly promote the process of intelligent manufacturing.