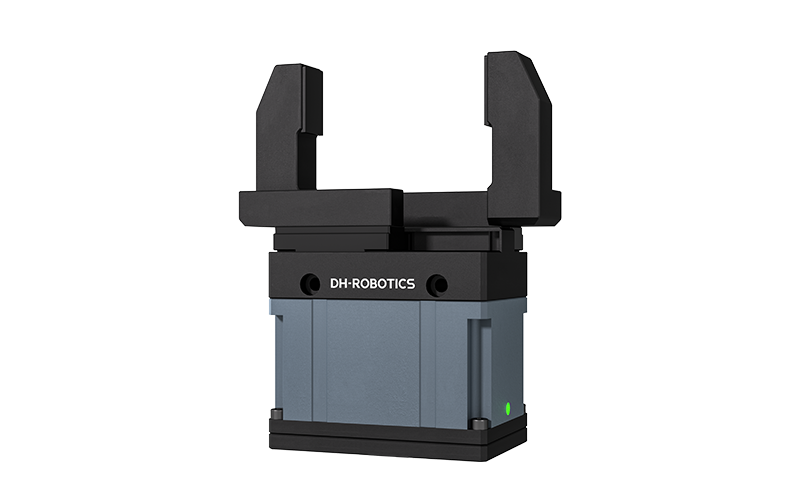

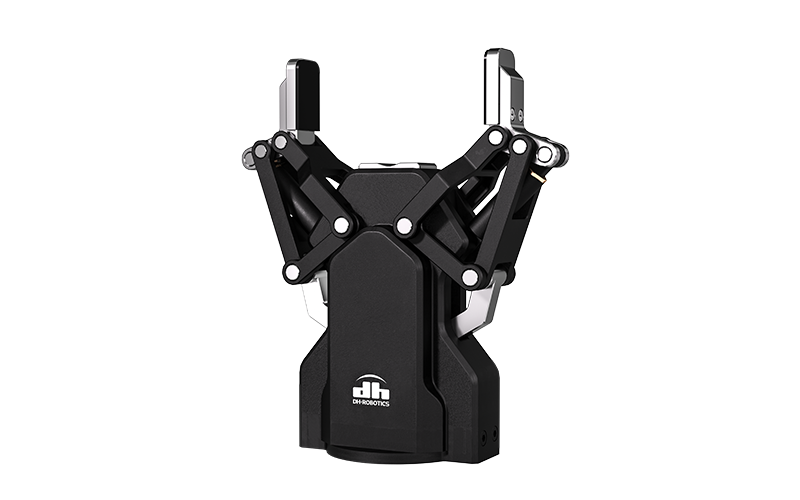

At the end of 2020, the RGI series of Industrial rotaty electric gripper developed by RH-ROBOTICS as the world’s first electric gripper capable of both clamping and infinite rotation, which can handle various tasks such as opening and closing lids, alignment, handing and installations. At the end of 2021, DH-ROBOTICS’ RGI series of Industrial rotaty electric gripper released a new upgraded version of the RGI-100, it offers more possibilities for smart manufacturing with more clamping force, more torque and a smaller footprint.

RGI-100 has a number of technical upgrades based on the previous generation of products. The maximum clamping force has been increased from 35 N to 100 N, and the maximum rotating torque has been increased by 5 times to 1.5 N·m, which can support richer workpiece gripping and rotating scenarios.

2 .Integrated | Double servo system

The first generation of the RGI series, the RGI-35, sloving the dilemma of infinite rotation and gripping in a small space in the industrial field with its sired double servo system. And this release of the upgraded version of the RGI-100 . Optimization of the structure has shortened the product length by 20 mm compared to the first generation, providing a variety of solutions for gripping needs in small spaces.3. High speed opening and closing | High repeatability

The RGI series of industrial rotaty electric gripper rotation repeatability of ± 0.02 degrees and position repeatability of ± 0.02 mm. With precise force and position control, the jaws are able to perform gripping and rotating tasks more stably. What’s more, the upgraded RGI-100, while maintaining high repeatability, further improves the gripper opening and closing speed. Which can be adapted to higher frequency gripping needs.

The RGI series of industrial rotaty electric gripper saving more than 60% in space and 30% in full-cycle cost compared to the nonstandard solution of gas-electric hybird combination based on ordinary servo motor design. Since its introduction, the RGI series has been recognized by customers for its excellent and stable performance, and has received unanimous praise from the market and customers. So far, RGI series has served more than 100 end-users, covering industries such sa medical antomation, 3C electronics, semiconductor, new energy, auto parts,etc. Currently, DH are leading the market share of rotary electric gripper.

DH firmly believe that as high-end intelligent manufacturing becomes more and more popular in the future, the RGI series represents a simple and flexible electric intelligent motion control module that can help the development of the industry. DH-ROBOTICS will also adhere to the core of the product, focus on the future, and bring more possibilities for “Intelligent manufacyurig in China”.